STOP, SMILE, and LISTEN

A Simple Habit That Can Change Your Entire Factory

Originally, I thought of writing this just for offsite factory owners and general managers, but as the words started to form, I realized something important: this message is for everyone. Everyone in an offsite construction factory. Everyone in any workplace, really. It’s about something so simple it almost sounds silly—and yet, it might just change your entire day.

It’s called: STOP, SMILE, and LISTEN.

Starting the Day on Empty

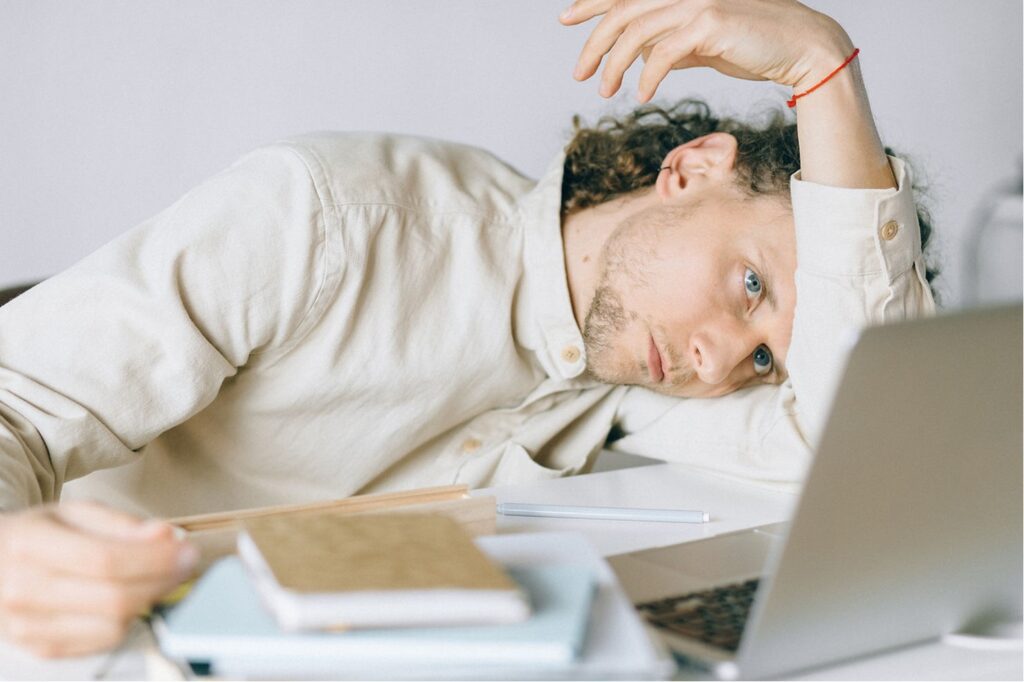

Imagine yourself as the owner or GM of an offsite construction factory. You’re building wall panels, components, or full modular homes. It’s 8:00 AM. You pull into your reserved parking space, walk through the front doors without making eye contact with anyone, and head straight to your office. You sit at your desk, take a deep breath, and wonder who or what is going to f**k up your day.

Sound familiar? That’s how far too many people start their morning—closed off, braced for the worst, and already wearing their frustration like armor. It’s not malicious. It’s just habit. But it’s also contagious.

Seeing What’s Already Going Right

Now let’s imagine something different. As you pull into that parking space, picture a big sign bolted to the wall in front of you: STOP, SMILE, and LISTEN.

So you stop. You look around. The production line is humming, your employees are already inside working, and trailers are lined up outside with modules ready to ship—real homes that someone chose to buy from your company. In the visitor parking area, you spot a couple of unfamiliar cars. Someone is here, right now, hoping to do business with your company.

That’s amazing, isn’t it? You just saw it—and appreciated it—instead of walking past it.

Creating Small Sparks of Connection

You step through the front door and are greeted by your receptionist. Normally you’d nod and keep walking, but today you stop.

“How are you doing this morning?” you ask.

“OK,” they answer, which these days can mean anything from “fine” to “hanging on by a thread.”

This is where you deliver your first SMILE of the day. “Just OK? It’s a beautiful morning out there.”

And suddenly, something shifts. They either agree and smile back, or maybe they open up about something personal—a sick child who’s finally better, a great dinner they had last night, or just the relief of finishing a tough week.

And you listen.

That simple, sincere moment has power. The person who greets everyone who walks in the door is now carrying a little spark of warmth, and they’ll pass it along to the next person who comes through. You don’t have to do it every day, but do it enough, and it becomes part of the air your team breathes.

Making It a Daily Practice

Keep doing this. Ask the receptionist who the visitors are meeting with. If someone new is talking with your corporate buyer, knock on the door, step in, shake their hand, and say, “Welcome to our factory.” Then walk out. That’s it. It’s not your job to buy things, but it is your job to build relationships.

A couple of times a week, stroll the production line. Stop for thirty seconds next to someone doing a great job or trying something new. Smile. Listen. Let them know you see them. Do the same with a salesperson you bump into in the hallway. These aren’t interruptions; they’re investments.

Why It Changes Everything

Before long, this practice rewires your mornings. The dread of “what’s going to go wrong today” gets replaced by “look at what’s already going right.” Negativity loses its grip.

Even better, you’ll start to really know the people who’ve chosen to work for you—their names, their stories, their talents. You’ll see them as more than job titles or productivity stats, and they’ll see you as more than a signature at the bottom of a paycheck.

And that is how workplaces transform—not with a grand announcement, but with one small decision made every day: STOP, SMILE, and LISTEN.