The environmental threat posed by plastics is well-documented, with mountains of non-biodegradable plastic waste accumulating in our oceans, fields, and even urban areas, causing significant harm to ecosystems and human health. As the world increasingly recognizes the urgency of addressing plastic pollution, industries are exploring innovative materials that balance functionality with environmental responsibility. One of the most promising solutions to emerge is bioplastic—a plant-based plastic that degrades without releasing toxic substances into the soil, offering a sustainable alternative to traditional plastics. This article explores the potential of bioplastics as a construction material, spotlighting current applications, challenges, and the path forward.

Exploring Bioplastics for Innovative Construction Projects

The Basics of Bioplastic: What Makes It Different?

Bioplastics are primarily derived from renewable plant materials such as corn, sugarcane, potatoes, and cellulose, rather than the fossil fuels traditionally used to make plastics. This plant-based origin significantly reduces the carbon footprint associated with plastic production. Additionally, bioplastics are designed to degrade naturally under specific conditions, meaning that, unlike petroleum-based plastics, they don’t persist in the environment for centuries. Some bioplastics are compostable, breaking down into non-toxic components that can even benefit the soil, unlike conventional plastics that contribute to microplastic pollution.

There are various types of bioplastics, each with distinct properties. For example, Polylactic Acid (PLA) is one of the most common bioplastics, used for food packaging and disposable items. Polyhydroxyalkanoate (PHA) is another type, noted for its versatility and biodegradability, with applications ranging from packaging to medical devices. The potential of bioplastics to revolutionize sustainable manufacturing is clear, yet they have so far been underutilized in construction—one of the world’s most resource-intensive industries.

Bioplastic in Construction: The ArboSkin Pavilion

The ArboSkin pavilion at Stuttgart University’s Institute of Building Structures and Structural Design (ITKE) is a pioneering example of bioplastic used in architecture. The pavilion, made from bioplastic comprising 90% renewable materials, demonstrates the feasibility of using bioplastics in construction applications. Its complex form was achieved through advanced fabrication methods, with the bioplastic panels shaped to create a striking organic structure. The project used an extruded bioplastic material that mimics traditional thermoplastic properties but is fully compostable, highlighting how bioplastics can be engineered for durability while remaining environmentally friendly.

This project was developed as part of a research initiative to explore sustainable materials in architecture. The success of the ArboSkin pavilion emphasizes bioplastic’s potential for architectural applications, particularly in façade systems and interior design elements where biodegradability and environmental impact are critical considerations. While still an emerging field, bioplastics in construction could serve as a cornerstone for eco-friendly architectural practices.

Advantages of Bioplastic in Construction

Reduced Environmental Impact: By replacing conventional plastics, bioplastics can decrease the amount of non-biodegradable waste generated. The plant-based origins also mean a reduction in fossil fuel reliance, leading to lower carbon emissions.

Health and Safety: Unlike certain synthetic building materials, which can emit volatile organic compounds (VOCs) and other toxins, bioplastics tend to have lower toxicity, reducing risks for construction workers and occupants.

Compostability and Recyclability: Bioplastics offer end-of-life options that traditional plastics do not. In the right facilities, bioplastics can be composted or recycled, providing a sustainable lifecycle from production to disposal.

Versatility in Design: Advances in bioplastic engineering allow for flexibility in molding and extrusion, which enables architects to experiment with complex shapes and designs, as seen in the ArboSkin pavilion.

Aesthetic Appeal: Bioplastics can be manufactured in various textures and finishes, making them suitable for both functional and decorative construction applications.

Challenges Facing Bioplastic in the Construction Industry

While the potential benefits are substantial, bioplastics face several challenges in their journey toward widespread adoption in construction:

Cost: Bioplastics are currently more expensive to produce than traditional plastics, largely due to limited economies of scale. As production methods improve and demand increases, the cost is expected to drop, but this remains a significant barrier for now.

Durability and Strength: Conventional plastics used in construction are valued for their strength and longevity. While bioplastics like those used in the ArboSkin pavilion demonstrate sufficient durability for certain applications, broader adoption will require further development to ensure long-term resilience under varying environmental conditions.

Lack of Awareness and Standardization: Many construction firms remain unaware of the options and benefits of bioplastics. Moreover, there is a lack of industry-wide standards to regulate the use and quality of bioplastics in construction, which hampers confidence and investment in the material.

Decomposition Requirements: Bioplastics typically require specific environmental conditions to decompose, such as industrial composting facilities, which may not always be available. Without the proper infrastructure, even biodegradable plastics can contribute to pollution.

Potential Applications in Construction

While bioplastics have yet to become mainstream in construction, several promising applications are on the horizon:

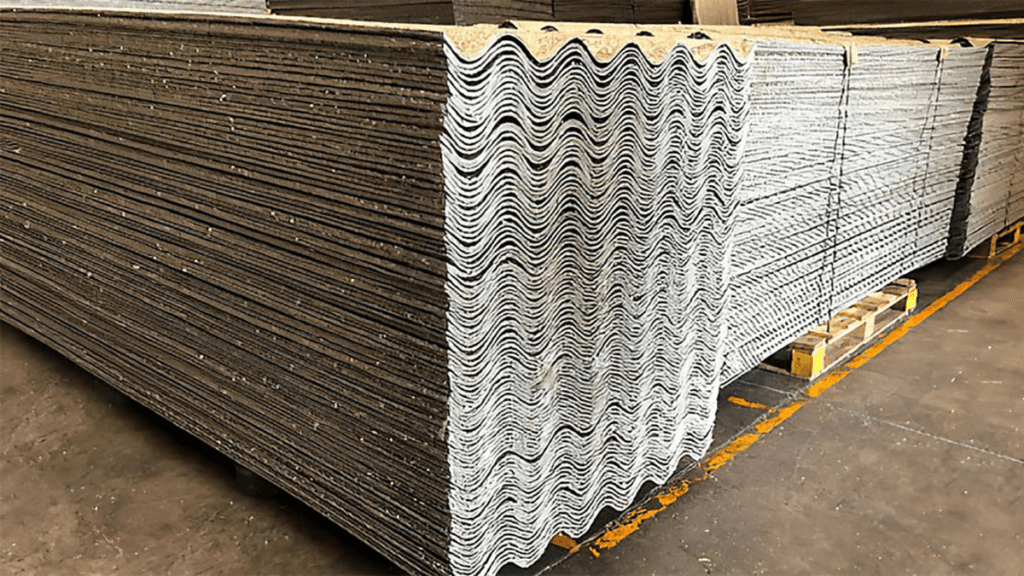

Façades and Cladding: Bioplastic panels, as demonstrated in the ArboSkin pavilion, could be used for façades and cladding, adding an eco-friendly element to building exteriors.

Insulation: Bioplastics could potentially be engineered to serve as sustainable insulation materials, providing energy efficiency while reducing environmental impact.

Interior Design Elements: Decorative panels, lighting fixtures, and even furniture made from bioplastics could transform interior spaces into sustainable environments.

Temporary Structures: For short-term construction projects or temporary housing solutions, bioplastics provide an excellent alternative due to their biodegradability, which reduces the waste associated with dismantling temporary structures.

Packaging and Protection: Construction materials often require packaging for transport and storage. Using bioplastic for these purposes can drastically reduce the waste generated during the construction process.

Sources of Bioplastic Supply for Construction

Currently, several companies are pioneering the production of bioplastic materials that could be adapted for construction applications. Here are some leading suppliers:

NatureWorks: This global leader in bioplastic production specializes in PLA-based materials, commonly used in food packaging and consumer goods but adaptable for light-duty construction applications.

BASF: Known for its biodegradable Ecoflex and Ecovio materials, BASF is exploring new ways to integrate bioplastics into various industries, including construction. Their products offer the durability of traditional plastics while being fully compostable.

Biome Bioplastics: This UK-based company produces a range of bioplastic materials with varying properties suitable for different applications, including sturdy, compostable bioplastics for the packaging and agricultural sectors. Their research and innovation could expand to the construction industry as demand grows.

.

Corbion: A major player in the PLA market, Total Corbion PLA offers high-quality bioplastics with a range of applications. As demand in the construction sector grows, companies like Total Corbion PLA are likely to expand their offerings to meet the needs of sustainable building materials.

Novamont: This Italian company specializes in fully compostable bioplastics and has developed a reputation for environmental responsibility. Their materials could be adapted for interior finishes and other applications within the construction industry.

The Innovative Future of Bioplastics in Construction

As construction industry leaders begin to prioritize sustainability, bioplastics offer a tangible solution to reducing the environmental footprint of building materials. For bioplastics to become a staple in construction, advancements in durability and cost reduction are necessary. Additionally, industry standards and certifications will play a critical role in ensuring bioplastics meet the rigorous demands of construction while preserving environmental benefits.

Collaboration among architects, engineers, and bioplastic manufacturers will be essential to drive bioplastic innovation in construction. As seen in the ArboSkin pavilion, bioplastics can achieve functional and aesthetic objectives, suggesting a future where buildings may be constructed with walls, roofs, and structural elements made from biodegradable materials.

While challenges remain, the path forward is promising. With sustained research and commitment to environmental goals, bioplastics may soon play a vital role in sustainable construction, reshaping how we build for future generations and redefining what is possible in eco-friendly architecture.

.