Offsite Innovators is all about showcasing the latest breakthroughs in construction, but every now and then, something old gets a fresh twist that catches my eye. That’s exactly what happened when I came across a company bringing wooden nails back to the construction industry.

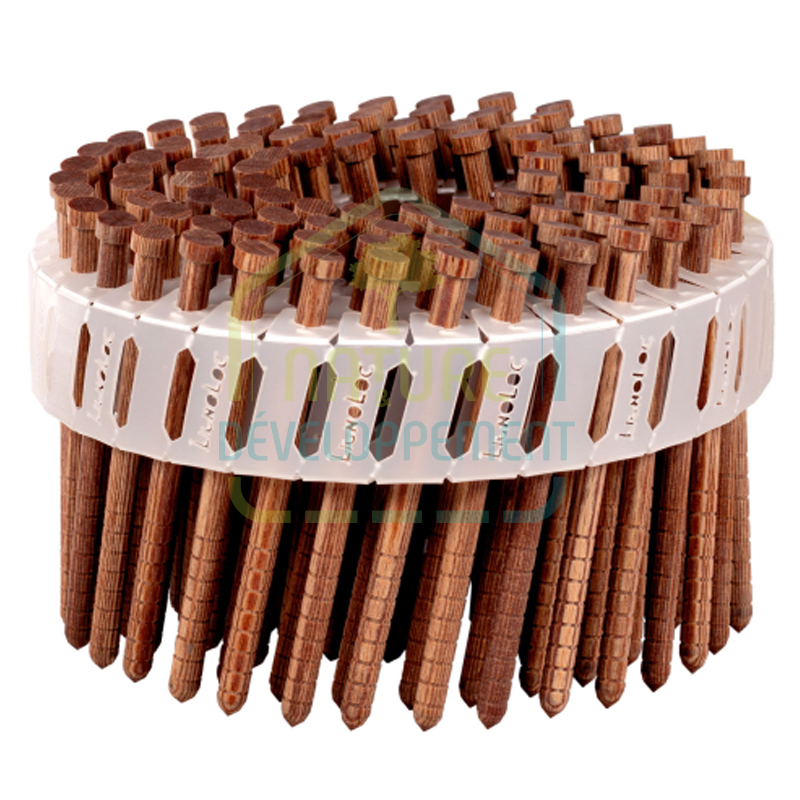

The world of construction is ever-evolving, with innovation constantly reshaping the tools, materials, and methods used to build the spaces we inhabit. Among the latest game-changers is LIGNOLOC®, the revolutionary wooden nail system developed by BECK Fastening Systems. Designed as a sustainable alternative to traditional steel nails, LIGNOLOC® has been making waves in the construction and woodworking industries. But what exactly makes this innovation so unique, and how is it reshaping the way we think about fastening?

The Origin of LIGNOLOC®

LIGNOLOC® wooden nails were born from BECK Fastening Systems’ commitment to sustainability and innovation. Recognizing the need for more eco-friendly solutions in construction, the company developed nails made entirely from European beech wood. These nails are hardened through a patented process, giving them the strength and durability needed for a variety of applications. The name “LIGNOLOC” itself hints at its primary material (“ligno” means wood in Latin) and its ability to “lock” materials together seamlessly.

The LIGNOLOC® system isn’t just a novel idea; it’s a fully functional fastening solution designed to integrate into pneumatic nailers for quick and efficient application. This innovation eliminates the need for metal fasteners in many projects, aligning perfectly with the growing demand for sustainable building practices.

How LIGNOLOC® Works

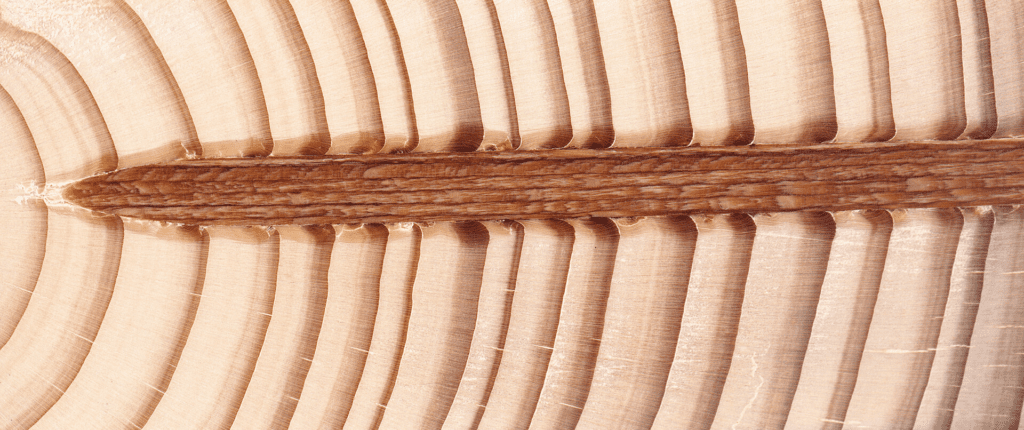

The magic of LIGNOLOC® lies in its unique design and application process. The wooden nails are installed using a specially designed pneumatic nail gun that drives the nails into the wood at high speeds. The friction generated during this process heats the lignin in the wooden nails, causing it to bond with the surrounding wood fibers. This creates a secure, permanent connection that’s as strong as traditional metal fasteners in many applications.

One of the standout features of LIGNOLOC® is its compatibility with other wood materials. Unlike metal nails, which can react with certain woods or corrode over time, LIGNOLOC® nails integrate seamlessly into the structure without compromising the material’s integrity. This makes them ideal for use in CLT (Cross-Laminated Timber) panels, furniture, and even boat building.

Key Benefits of LIGNOLOC®

LIGNOLOC® offers a range of benefits that make it a compelling choice for builders, carpenters, and manufacturers:

Sustainability: Made from renewable beech wood, LIGNOLOC® nails significantly reduce the environmental impact of construction projects. Their production involves less energy and fewer emissions compared to steel nails.

Aesthetic Appeal: For projects where the appearance of exposed fasteners matters, LIGNOLOC® nails blend seamlessly with wood surfaces, providing a clean and natural look.

Corrosion Resistance: Unlike metal nails, wooden nails don’t corrode over time. This makes them an excellent choice for outdoor applications and projects in humid or marine environments.

Efficient Workflow: The pneumatic nail gun ensures quick and precise installation, saving time on the job site and improving productivity.

No Thermal Bridging: Metal fasteners can create thermal bridges, reducing energy efficiency in structures. Wooden nails eliminate this issue, contributing to better insulation performance.

Applications of LIGNOLOC®

LIGNOLOC® is versatile enough to be used across a variety of industries and applications. Here are a few areas where these innovative wooden nails are making an impact:

Wooden Facades and Cladding: LIGNOLOC® nails provide a durable and aesthetically pleasing solution for attaching wooden panels without the need for visible metal fasteners.

Furniture Manufacturing: The seamless integration of wooden nails enhances the natural beauty of wooden furniture and reduces the need for adhesives or screws.

CLT and Timber Construction: In mass timber projects, LIGNOLOC® nails contribute to the structural integrity of beams and panels while aligning with sustainability goals.

Boat Building: The non-corrosive nature of wooden nails makes them ideal for marine applications, where exposure to water is constant.

Historical Restoration: For restoration projects requiring period-accurate materials, LIGNOLOC® nails provide a modern yet authentic alternative.

Challenges and Limitations

While LIGNOLOC® offers numerous advantages, it’s not without its challenges. One of the primary limitations is its strength in comparison to metal nails in certain high-load applications. While wooden nails are suitable for many uses, steel fasteners may still be required for projects involving extreme stress or heavy-duty materials.

Additionally, the cost of LIGNOLOC® nails and the specialized pneumatic nailer may be a barrier for smaller contractors or DIY enthusiasts. However, as the technology becomes more widespread, it’s likely that costs will decrease, making it more accessible to a broader audience.

A Step Toward Sustainable Construction

The introduction of LIGNOLOC® aligns with a broader shift in the construction industry toward more sustainable practices. As governments and organizations push for greener building standards, innovations like wooden nails are becoming increasingly important. By reducing reliance on metal fasteners, LIGNOLOC® contributes to lowering the carbon footprint of construction projects and supports circular economy principles.

Moreover, the use of LIGNOLOC® in mass timber construction has the potential to revolutionize how we think about large-scale building projects. The combination of timber’s natural carbon-sequestering properties with the sustainability of wooden nails creates a compelling case for their adoption in future developments.

Looking Ahead

LIGNOLOC® is more than just a new product; it represents a paradigm shift in how we approach fastening in construction. By combining innovative technology with a commitment to sustainability, BECK Fastening Systems has introduced a solution that meets the needs of modern builders while addressing environmental concerns.

As the construction industry continues to evolve, the success of LIGNOLOC® will likely inspire further innovations in sustainable building materials. Whether you’re a contractor, carpenter, or architect, it’s worth keeping an eye on how this revolutionary product shapes the future of construction. With its blend of practicality, environmental responsibility, and aesthetic appeal, LIGNOLOC® wooden nails are driving a new era of eco-conscious building practices—one nail at a time.