In talking recently with an Offsite modular manufacturer I was impressed with their interest in a relatively new innovative air distribution system that appears to have many distinct advantages not only for modular manufacturers but also for site built multilevel projects. After contacting Rheia and talking with Nigel Watts VP at Rheia, their product does have all the earmarks of an innovative approach that bears further exploration.

Nigel Watts, Vice President of RHEIA, LLC

Bill Murray, Offsite Innovators: Would you give us a brief history and description of your company?

Nigel Watts,VP Rheia HVAC Stystems: Rheia’s journey began in 2019 after nearly a decade of research, development, and rigorous testing of an innovative HVAC air distribution system designed for optimal efficiency and enhanced comfort. Backed by capital from seven of the nation’s largest homebuilders, leading industry manufacturers, and numerous individual investors, Rheia assembled a team of seasoned manufacturing, supply chain, and software development experts dedicated to redefining comfort and efficiency in homebuilding. In the spring of 2020, Rheia launched our first pilot home, marking the beginning of a new era in HVAC technology. Rheia is currently active in most major homebuilding markets in the US and is installed in over 20,000 homes in the US and Canada.

Bill Murray: Rheia touts an innovative system that revolutionizes the installation of Hvac products in the homebuilding industry. Would you describe your unique system?

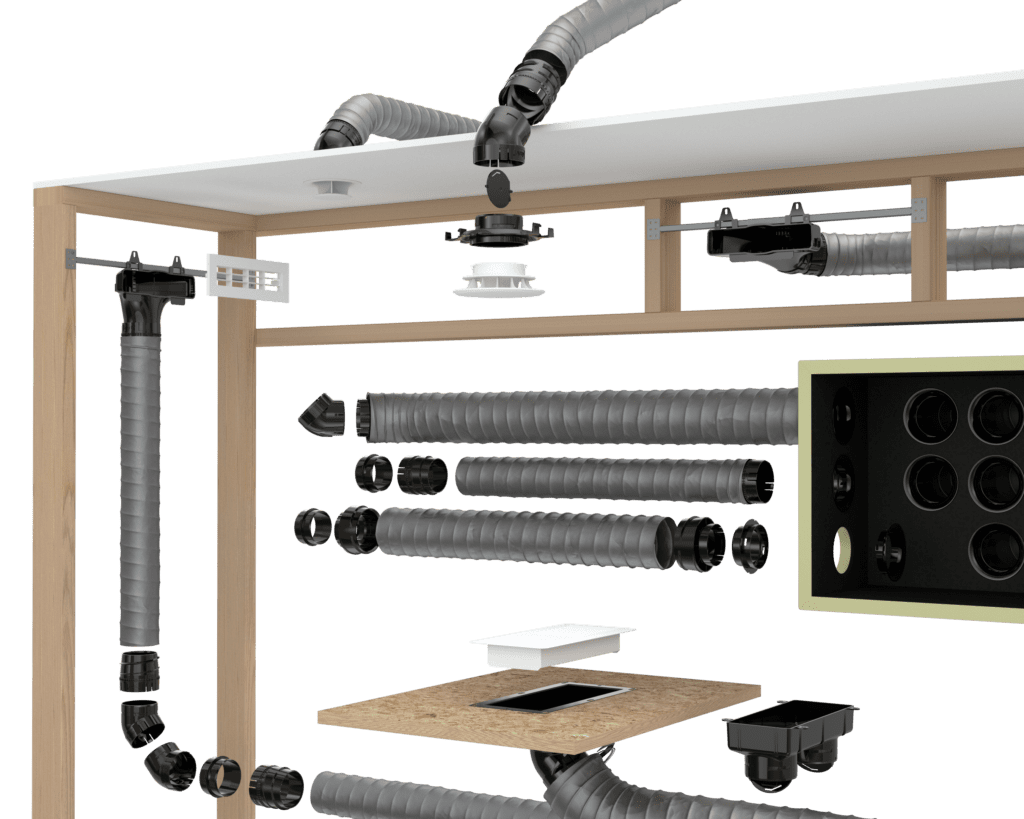

Nigel Watts: Rheia is a home-run, small-diameter air distribution system installed within the home’s conditioned space, designed to reduce energy use and improve HERS scores. The system features durable, uninsulated ducts and engineered thermoplastic fittings that quickly assemble to create sealed connections without the need for imprecise, messy duct mastic. Rheia is engineered for easy installation, boosting productivity for HVAC contractors in an industry facing labor shortages. Paired with the industry-first Rheia Verify balancing app, the system enhances thermal comfort and minimizes the costly callbacks commonly seen with conventional duct systems.

Bill Murray: How does the Rheia approach differ from conventional, traditional HVAC applications making it truly innovative?

Nigel Watts: Rheia’s air distribution system changes the game by dramatically simplifying installation. It can reduce installation time by up to 60%, to keep projects on track and maintain high productivity despite workforce shortages. Training for the installation process can be accomplished in mere minutes.

Balancing a traditional HVAC system is another headache—it’s labor-intensive, error-prone, and often leads to uneven temperatures and higher energy bills. Many systems fail to consider the home’s orientation, leading to inefficiencies that require multiple site visits, increasing costs and frustrating customers.

Rheia tackles these problems with its Verify App, a powerful tool that simplifies the complex balancing process into just 10 straightforward steps, taking only 30 to 45 minutes to complete. The app guides technicians through each stage, from verifying equipment settings to adjusting blower speeds and entering room airflows. This ensures that the system operates as intended, reducing the risk of costly errors and ensuring customer satisfaction.

In short, Rheia’s air distribution system and Verify App streamline the installation and balancing of HVAC systems, improving performance, reducing costs, and addressing labor challenges. This innovative approach ensures that HVAC systems work efficiently and effectively, leading to happier customers and more successful projects.

Bill Murray: What are the significant advantages to a builder in using the Rheia system?

Nigel Watts: While solutions like conditioned attics and deeply buried ducts can help reduce heating and cooling costs, Rheia takes a more efficient approach by installing ductwork within the home’s thermal envelope. This method is faster, easier, and more cost-effective. Recent code changes, upgraded tax rebates, and energy incentives are pressuring builders to improve the energy performance of their homes.

The most cost-effective way to meet these new requirements is to move ductwork inside the home’s conditioned space. The challenge they face, however, is that it is costly to make this change. Due to the complexities of rerouting bulky, insulated ducts or creating conditioned attic spaces, Rheia’s compact system is the only cost-effective way to bring ducts into conditioned space. Beyond the financial benefits, builders can also realize improved HERS scores with this approach, improving the marketability of their homes.

Bill Murray: What are the specific advantages of the Rheia products to the Offsite building industry, particularly to the volumetric modular industry?

Nigel Watts: The Rheia system is a highly engineered solution designed for efficiency and precision. Its high-performance components snap together seamlessly, eliminating the need for time-consuming post-operations such as air sealing after assembly. This approach is perfectly aligned with the volumetric homebuilding approach, which emphasizes a systems-based method of manufacturing that thrives on consistent, repeatable processes.

Rheia’s straightforward design allows installation crews to be trained in just minutes, a significant advantage in an industry facing skilled labor shortages. This combination of simplicity, speed, and reliability makes Rheia an ideal choice for modern homebuilding, where efficiency and consistency are paramount.

Bill Murray: This appears to be a different approach to HVAC installation. How does Rheia provide training and support for new HVAC contractors?

Nigel Watts: Rheia takes a hands-on approach to guide a contractor through the change management process providing on-site training and easy-access resources. We pride ourselves in our dedication to supporting contractors as they transition to Rheia.

How has your product been accepted in an industry that often resists change? What are your plans and goals short term as well as long term?

At Rheia, LLC, we’ve observed a wide variety of reactions from builders and contractors as they encounter our system. The homebuilding industry, with its deeply ingrained practices and reliance on traditional methods, can be resistant to change. This resistance is understandable; altering established processes can disrupt workflow retraining, have the potential to impact financial results, and initially seem risky.

However, we’ve found success when partnering with companies that are open to exploring new solutions and willing to embrace the benefits that come with innovation. These forward-thinking builders and contractors recognize that while the transition may pose challenges, the long-term gains—such as improved energy efficiency, reduced installation time, and enhanced system performance—are well worth the effort.

Above all, we’ve learned that patience is essential when introducing new products to the market. Change management in this industry requires time, persistence, and a deep understanding of the challenges builders and contractors face. We are committed to working closely with our partners, providing the necessary tools, training, and support to ensure a smooth transition and, ultimately, a successful integration of Rheia’s advanced air distribution systems into their projects.

The future is bright for Rheia, and for the industry. Gradually, we are having an impact n and refining our business processes and understand of how to make change as painless as possible for our customers. Looking forward, Rheia will be expanding into new segments of the residential homebuilding market, and we have a range of exciting new products already in the works.

Bill Murray: Thanks to Nigel Watts, VP at Rheia for the introduction to an innovative approach to hvac distribution systems. In talking with several modular manufacturers they have expressed a keen interest in this system. Be innovative……check it out.

Reader interactions

2 Replies to “Innovative HVAC system that dramatically reduces installation labor and design constraints, while increasing efficiency.”

We are looking for supply chain partners in all aspect of the construction industry. As we have developed new modular structural platform, we would like to understand your system a lot better to see if we can integrate this as HVAC Option system.

could advise if we can meet online to understand this further.

thanks.

Property owners should read this.