Is Big Brother Watching?

In modular and offsite construction, innovation often takes the form of new materials, advanced building techniques, or cutting-edge factory processes. But what if the next leap forward wasn’t about physical improvements, but rather about how we monitor and understand the work we’re already doing? Picture a factory where every movement, every piece of equipment, and every material is being quietly observed and analyzed in real-time by an intelligent system. This system isn’t just watching—it’s learning, predicting, and optimizing. This isn’t science fiction; it’s a growing reality as AI-driven video systems become an integral part of modern manufacturing and construction.

.

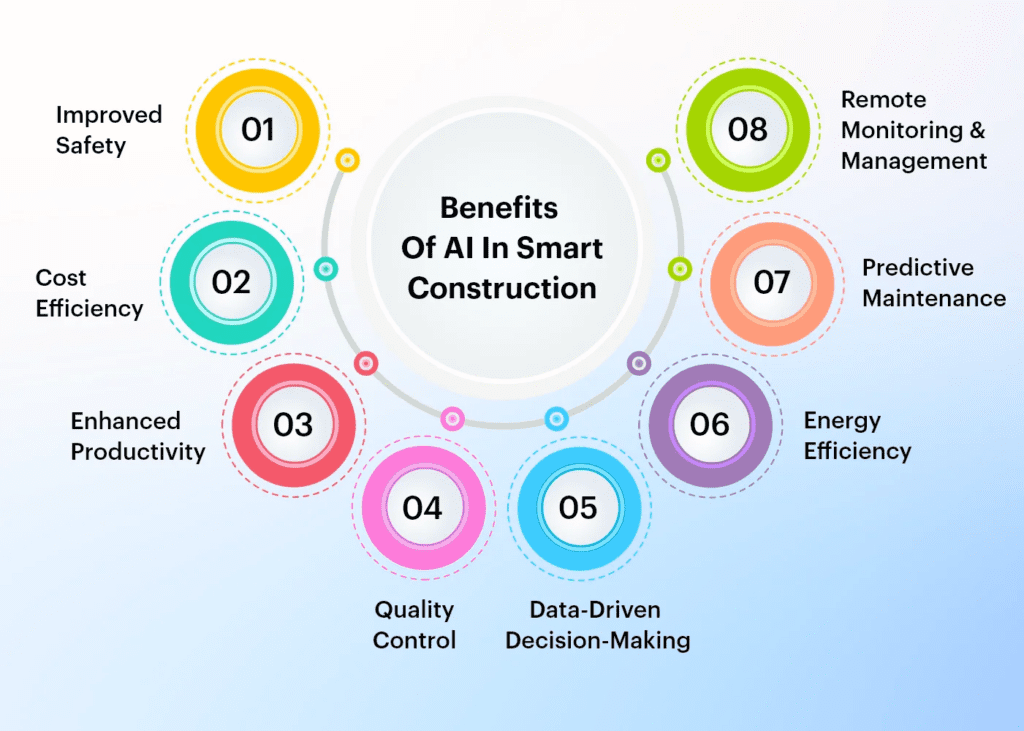

For modular and offsite construction factories, the introduction of AI-based video analytics is poised to be a game changer. By installing video cameras throughout the factory floor, offices, and yard areas, factory managers can now access a live feed of data processed by sophisticated software capable of learning and making real-time decisions. This technology offers a detailed, dynamic view of operations, unlocking new opportunities for efficiency, safety, and productivity. More importantly, it’s an innovation that isn’t about creating something entirely new, but about enhancing and reimagining existing processes.

The Power of AI in Monitoring Modular Construction

The nature of modular and offsite construction—where components are prefabricated in factories before being shipped to building sites—lends itself perfectly to the use of AI video systems. These systems allow factory managers to gather crucial insights into the performance of their operations, ranging from workflow bottlenecks to worker safety. But what makes this technology especially exciting is how it can provide this information continuously and automatically, without the need for manual supervision.

Imagine a large factory assembling modular housing units. Video cameras positioned throughout the factory feed live footage into an AI-based software system. The AI isn’t just looking for obvious problems; it’s analyzing every detail, comparing it against hundreds of hours of historical data to find patterns that human observers might miss.

For example, the AI might notice that workers in one section of the assembly line consistently take longer to complete their tasks on certain days of the week. By comparing this information with footage of how materials are being delivered and used, the system could identify that delays in material restocking are causing slowdowns. This insight allows managers to adjust the schedule or improve material handling processes, reducing downtime and keeping production on track.

This is just one example of how AI can offer unprecedented insights into modular construction, and it’s only the beginning.

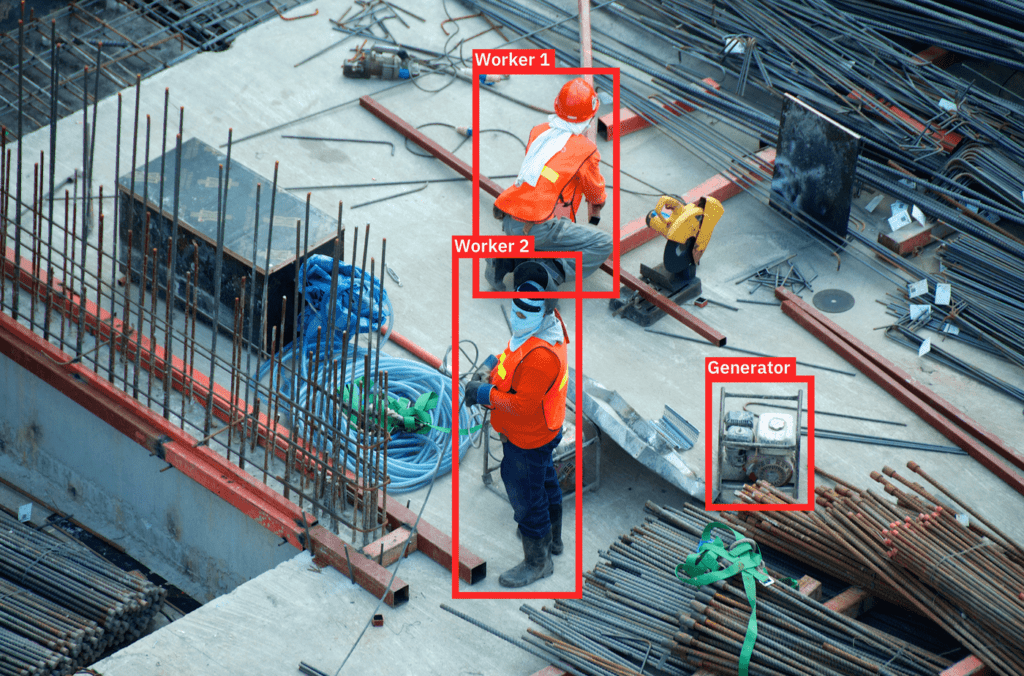

Enhancing Safety with AI Video Monitoring

Safety is a top priority on any construction site, and modular construction factories are no exception. But while factory environments are generally safer than on-site construction work, risks still exist. AI-powered video systems provide a way to monitor safety in real-time and prevent accidents before they happen.

The AI can be trained to recognize unsafe behaviors, such as workers neglecting to wear personal protective equipment (PPE), handling machinery improperly, or even working in dangerous proximity to heavy equipment. When the system detects a potential safety violation, it can immediately alert a supervisor or shut down equipment to prevent accidents.

Take the example of a worker who regularly bypasses safety protocols by not using harnesses or proper lifting techniques. While human supervisors may not always be able to catch these violations, AI-powered cameras can identify these risky behaviors consistently. By flagging these issues in real-time, the system not only protects the individual worker but also helps create a culture of safety throughout the factory.

.

Companies such as Procore are already providing AI-based safety monitoring solutions for construction sites. These systems analyze video data to detect hazards and safety violations, offering companies a way to proactively manage risks and avoid costly accidents.

Increasing Operational Efficiency

AI-driven video analytics can also transform operational efficiency in modular construction factories. In a factory setting, every second counts. Delays, bottlenecks, and inefficiencies can quickly add up to significant lost time and money. With AI-powered video, managers can get a bird’s-eye view of the entire operation, tracking every movement, material, and machine in real-time.

.

For instance, if an assembly line is slowing down, the AI can track the flow of materials and workers to pinpoint exactly where the issue lies. It could be a machine that’s out of sync, workers who are waiting for materials, or even a storage area that’s too far from the production line. With this data, managers can make targeted adjustments to optimize the workflow.

One company that’s already implementing AI-driven monitoring is Siemens. In their advanced manufacturing facilities, they use AI-powered cameras to monitor the production line, ensuring everything runs smoothly and on schedule. If a machine is operating slower than expected, the system alerts operators to check for maintenance needs before a breakdown occurs. This predictive approach can reduce downtime significantly.

In the modular construction industry, where timelines are often tight, these kinds of insights can mean the difference between a project being completed on time and one that is delayed.

Monitoring Employee Well-Being

It’s not just machines and materials that can benefit from AI video systems; workers themselves are also under the watchful, non-intrusive eye of this technology. In fast-paced factory environments, employee fatigue and stress can become major concerns, leading to mistakes, injuries, or decreased productivity. AI-powered video systems can monitor worker behavior, identifying signs of fatigue or stress.

For instance, if a worker starts taking more frequent breaks or shows signs of reduced productivity, the AI can detect these changes and alert managers. This allows for interventions—such as adjusting workloads or offering additional breaks—before the worker becomes too fatigued, preventing burnout and accidents.

This kind of monitoring doesn’t just improve safety; it also helps maintain a healthy, happy workforce, which in turn leads to greater productivity and job satisfaction.

Revolutionizing Inventory Management

In a modular construction factory, managing materials and inventory is a critical task. Delays in receiving materials or misplacing valuable components can cause costly slowdowns in the production process. AI-powered video systems can offer real-time inventory tracking, helping factories maintain better control over their stock.

Cameras positioned in storage areas can monitor how materials are being used and where they’re stored. The AI can track patterns, ensuring that materials are replenished before they run out and even suggesting optimal storage layouts to reduce time spent retrieving items. This data can help prevent bottlenecks caused by material shortages and streamline the flow of materials from storage to the assembly line.

Companies like Amazon are already using AI-powered cameras in their warehouses to optimize inventory management. In the same way, modular construction factories could use this technology to manage materials, reduce waste, and ensure that every part of the production process is adequately supplied.

Predictive Maintenance and Machine Monitoring

AI-powered cameras are not only useful for tracking materials and employees but also for monitoring the condition of machinery. In a modular construction factory, equipment is often used intensively, leading to wear and tear that can cause breakdowns. However, by analyzing video footage, AI can detect early signs of mechanical problems—such as unusual vibrations, leaks, or overheating—before they cause major issues.

With this predictive maintenance approach, machines can be repaired or serviced at optimal times, reducing the likelihood of unexpected breakdowns. This helps factories avoid costly downtime and ensures that production stays on schedule. Companies like GE are already using AI to monitor and predict the maintenance needs of their equipment, offering a proven model that could be adapted to modular construction.

A Glimpse into the Future

While this kind of AI-driven video monitoring may sound futuristic, it’s already being used in industries ranging from retail to manufacturing. Companies like Walmart use AI cameras to track customer behavior and prevent theft. The modular construction industry is ripe for adopting this kind of technology, and forward-thinking companies are beginning to explore how AI video systems can revolutionize their operations.

In the near future, it’s likely that more modular construction factories will integrate AI-based video systems into their processes. Whether it’s improving safety, streamlining operations, or enhancing inventory management, these systems offer a wealth of benefits. And as transportation costs continue to rise, these insights could also drive the revival of an old innovation—standardized components—delivered efficiently and assembled on-site.

By embracing AI-driven video systems, modular and offsite construction factories will not only improve their efficiency and safety but also gain a competitive edge in an increasingly demanding market. As the old adage goes, sometimes the best innovations aren’t about creating something new, but about making the most of what we already have. And in the case of AI-driven video systems, the future looks bright indeed.

.