If you’ve ever heard the term carbon-neutral construction tossed around at a conference or slipped into a sales pitch, you may have nodded politely while wondering what it actually means. It sounds like one of those trendy buzzwords consultants and marketers love to throw into presentations. But for offsite construction, carbon-neutral isn’t just another industry fad—it’s quickly becoming a line in the sand for owners, investors, and regulators. And the truth is, it’s not nearly as complicated as some would have you believe. Let’s pick up the “big crayons” and draw it out clearly.

What Carbon-Neutral Means in Plain English

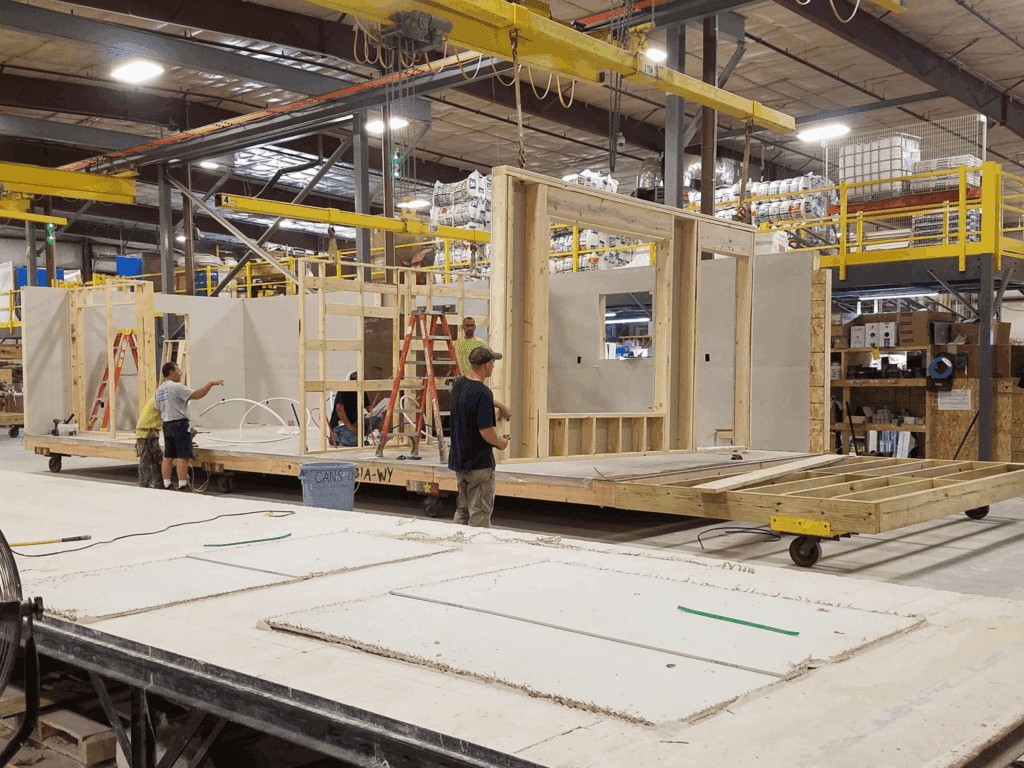

Every time a factory builds a module, a wall panel, or even a truss, carbon dioxide (CO₂) is released somewhere along the way. Cement plants, steel mills, lumber drying kilns, diesel-powered trucks, and even the electricity running saws and nail guns all contribute to the carbon “footprint” of a project.

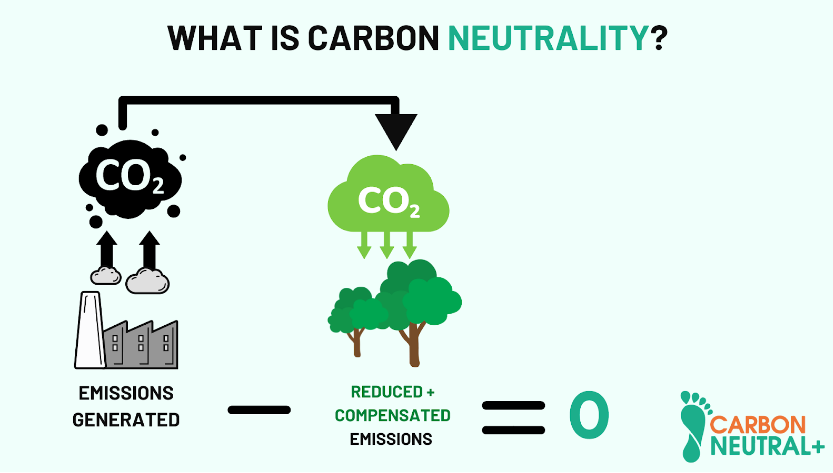

Carbon-neutral means two simple things:

- Cut down emissions where you can. Use greener materials, smarter production methods, and efficient transportation.

- Clean up what’s left. Buy offsets like reforestation projects, renewable energy credits, or investments in carbon removal technology.

The idea is that when you tally it all up, the CO₂ your project put into the air has been canceled out by CO₂ taken out somewhere else. Net impact: zero.

Why It Matters to Offsite

For decades, offsite manufacturers have fought the uphill battle of convincing the world that factory-built doesn’t mean flimsy or cheap. In fact, the industry has made enormous strides in quality, safety, and speed. Now comes another opportunity: showing that offsite construction can lead the way in sustainable building.

Why does this matter? Because the biggest buyers of housing, commercial spaces, and even government-funded projects are demanding it. Developers want carbon-friendly buildings to attract investors. Cities are passing green building codes. Lenders are tying financing rates to sustainability goals. And perhaps most importantly, the next generation of homebuyers—Millennials and Gen Z—are far more likely to value eco-conscious construction than their parents ever were.

For offsite, this is a chance to stand out. Factories already run on repeatable, controlled processes. They waste less material than job sites. They use precision that site-built crews often can’t match. Leaning into carbon-neutral practices allows offsite companies to take what they’re already doing right and prove they’re miles ahead of traditional construction.

But Doesn’t This Cost More?

Let’s be honest: yes, it adds cost. But maybe not as much as you think.

- Materials: Switching to low-carbon concrete or mass timber may run 1–5% higher than traditional materials. For a single-family home, that could be a few thousand dollars. For a multifamily project, it’s more—but still within reason compared to the overall budget.

- Offsets: Purchasing carbon offsets adds another small layer. For an average house, offsets might cost less than the kitchen appliance upgrade. For a mid-sized development, they’re a fraction of the marketing budget.

And here’s the kicker: carbon-neutral buildings save money in the long run. Factories that optimize for energy efficiency spend less on power. Finished homes that are designed for low energy use cut utility bills for the buyer, making them more marketable. In the big picture, the return on investment often outpaces the upfront cost.

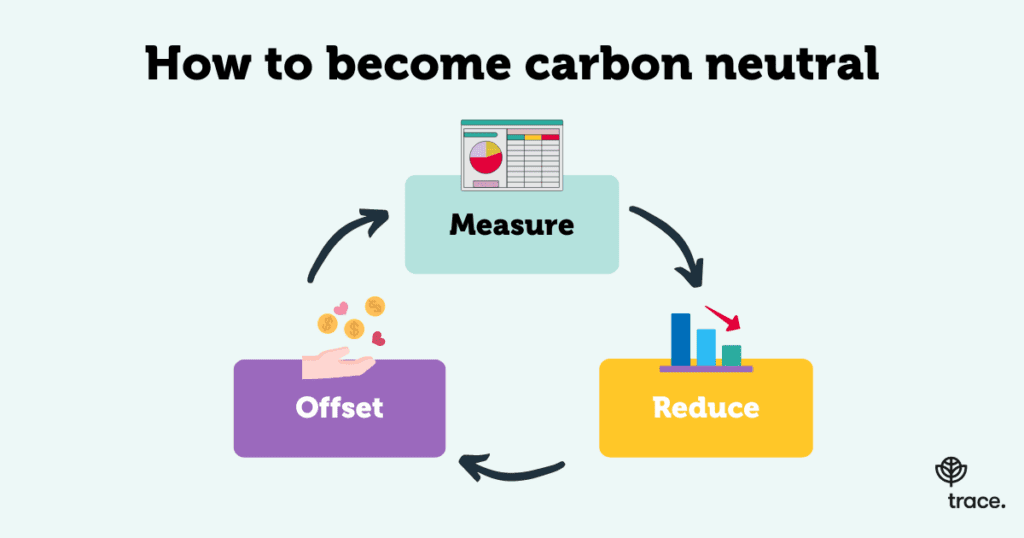

Can You Actually Measure This?

This is the part where people start to squirm. Measuring carbon emissions sounds like a fuzzy science experiment. But the reality is, it’s surprisingly trackable.

- Materials: Cement, steel, and lumber all come with well-documented emission factors.

- Transport: Diesel use can be calculated down to the gallon.

- Factory Energy: Electricity and natural gas consumption are already on the utility bills.

Add it up and you get a pretty clear picture of how much CO₂ your project produced. Where it gets trickier is the offsets—like planting trees. A sapling today may not absorb significant carbon for years, and there’s always the risk it doesn’t survive. That’s why serious offset providers are held to certification standards to make sure the “clean-up” is real.

So yes, it’s measurable. Not perfect, but close enough to make it a serious tool rather than just a feel-good idea.

The Bigger Opportunity

Carbon-neutral isn’t just a cost or a box to check; it’s a chance for offsite construction to redefine itself. While site-built contractors are still wrestling with mountains of waste, inefficiency, and inconsistent building practices, offsite has the chance to say: We’re not only faster and more precise—we’re cleaner too.

Imagine a factory marketing its product as “the first carbon-neutral homes in the state.” Imagine developers pitching investors a multifamily project that’s net-zero impact from day one. Imagine local governments awarding contracts based not only on cost and timeline, but on carbon performance. Those scenarios aren’t futuristic—they’re already happening in pockets across North America and Europe.

The Bottom Line

Carbon-neutral construction doesn’t mean building with hemp rope and fairy dust. It means building smarter, reducing waste, and being accountable for the footprint we leave behind. Yes, it costs a little more today, but it’s quickly becoming the standard that owners, regulators, and buyers expect.

For the offsite industry, the message is clear: step up and lead, or risk being seen as just another old-school builder hiding in a factory.

Carbon-neutral is coming. The question is—will offsite construction be the one holding the crayon and drawing the path forward?