The era of humanoid robots has arrived, transforming what once seemed like a distant dream into a groundbreaking reality that’s reshaping industries—including offsite construction. These remarkable machines, designed to mimic human movement, expressions, and even problem-solving abilities, are poised to revolutionize how modular homes and prefabricated buildings are conceived, constructed, and delivered. Humanoid robots are not merely tools; they are collaborators, working alongside human teams to enhance efficiency, precision, and creativity in one of the most innovative construction sectors.

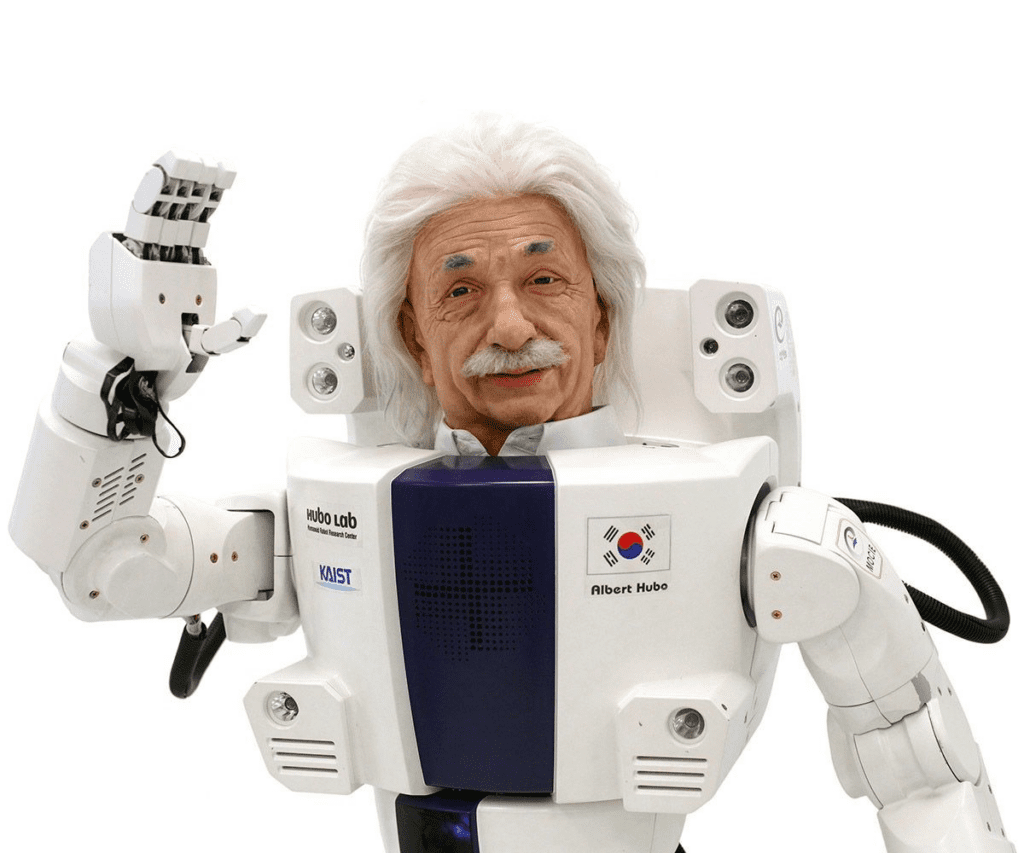

The Albert Hubo Robot

Imagine a modular construction factory where humanoid robots move seamlessly among workers, assembling components with unparalleled dexterity and consistency. Equipped with cutting-edge technologies like advanced AI, natural language processing, and adaptable mechanics, these robots can perform complex tasks, from handling delicate materials to inspecting completed modules for quality assurance. Their ability to learn and adapt on the job could address the industry’s labor shortages while streamlining production timelines and reducing errors, offering builders and developers a competitive edge in a demanding market.

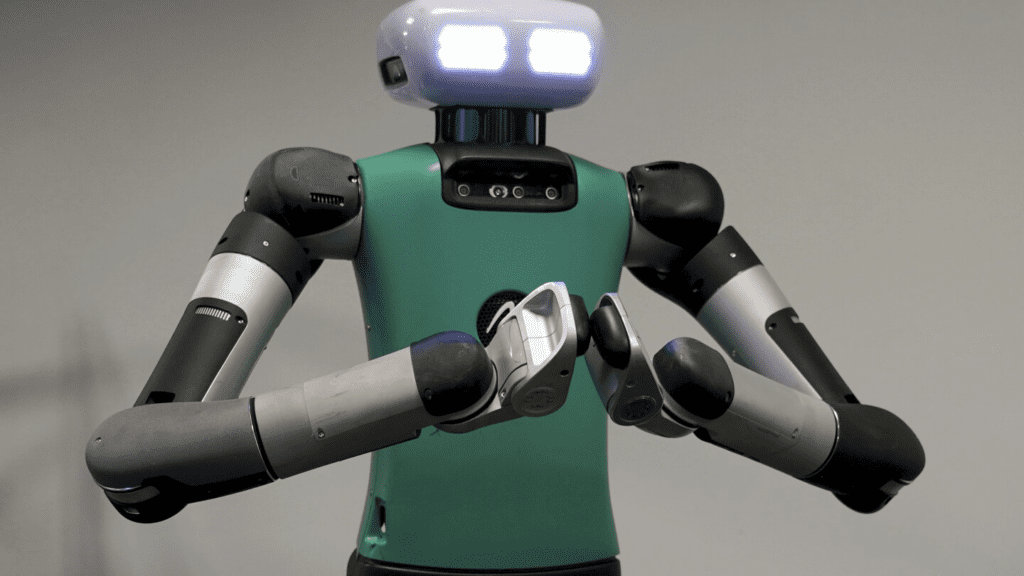

Agility Robotics

Beyond their technical capabilities, humanoid robots offer a glimpse into the future of offsite construction—a future defined by collaboration between human ingenuity and robotic precision. Their introduction raises exciting possibilities for creating safer work environments, where robots take on repetitive or hazardous tasks, freeing human workers to focus on creative problem-solving and innovation. As the boundaries of robotics and construction continue to blur, the industry is presented with opportunities to rethink not just how buildings are made but also how the entire construction process can become more efficient, sustainable, and scalable.

For the offsite construction industry, humanoid robots represent more than just technological progress—they are a symbol of what’s possible when advanced robotics meet a forward-thinking sector. Whether it’s assembling structural components, optimizing logistics, or ensuring quality at every step, these robots are setting the stage for a new era of construction. The humanoid revolution is here, and its impact on offsite construction is just beginning to take shape.

Here are some of the leaders working to bring humanoid robots to the workspace:

Tesla (United States)

Robot: Optimus

Overview: Unveiled in 2021, Optimus is designed for general-purpose tasks, aiming to perform duties that are “dangerous, repetitive, and boring”. Tesla plans to commence low-volume production by 2025, with a target price between $20,000 and $30,000.

Agility Robotics (United States)

Robot: Digit

Overview: Founded in 2015, Agility Robotics developed Digit, a bipedal humanoid robot designed for logistics and warehouse tasks. Digit has been deployed in facilities such as a Spanx warehouse and is being tested by companies like Amazon for distribution and fulfillment tasks.

Figure AI (United States)

Robots: Figure 01 and Figure 02

Overview: Established in 2022, Figure AI focuses on creating AI-powered humanoid robots for manual labour. In 2024, the company secured $675 million in funding from investors including OpenAI, Microsoft, Nvidia, and Jeff Bezos, valuing the company at $2.6 billion. Figure 02 robots have been deployed in BMW’s manufacturing facilities for testing.

Hanson Robotics (Hong Kong)

Robots: Sophia, Albert Hubo, Bina48

Overview: Hanson Robotics is renowned for developing human-like robots capable of human interaction and emotional intelligence. Sophia, one of its most famous robots, was activated in 2016 and has been granted citizenship in Saudi Arabia. Also behind the AiDa humanoid robot, which sold its painting for more than $1 million at Sotheby’s auction house recently.

.

UBTech Robotics (China)

Robot: Walker S1

Overview: UBTech has developed Walker S1, a humanoid robot designed for manual labour tasks in manufacturing settings. These robots have been deployed in BYD Auto’s factories to address labour shortages and enhance efficiency.

1X (Norway)

Robots: Eve and Neo Beta

Overview: Founded in 2014, 1X develops humanoid robots emphasizing safety and affordability. EVE is designed for roles in security, healthcare, and other service-oriented industries, while Neo Beta is a humanoid robot for home use, currently being tested in domestic environments.

Sanctuary AI (Canada)

Robot: Phoenix

Overview: Sanctuary AI focuses on creating humanoid robots with human-like intelligence to assist in various work environments, enhancing safety and efficiency. Phoenix is their general-purpose robot designed to perform a wide range of tasks across different industries.

Fourier Intelligence (China)

Technology of interest: Intelligent Rehabilitation Robots

Overview: Fourier Intelligence specializes in developing intelligent humanoid robots for medical rehabilitation. Their products are deployed in over 2,000 clients across more than 40 countries, providing high-performance rehabilitation solutions.

Boston Dynamics (United States)

Robot: Atlas

Overview: Boston Dynamics’ Atlas is a bipedal humanoid robot designed for search and rescue tasks. Unveiled in 2013, Atlas demonstrates advanced athletics and agility, exploring the potential of the humanoid form in dynamic environments.

CLICK HERE to read the original Robotic and Automation News article