Sustainability, through the use of readily available Ponderosa Pine, redefined by Timber Age Systems

Several weeks ago I had an opportunity to learn about a panelized start-up in Durango, CO. I was immediately struck by their innovative approach to maximizing sustainability through the use of readily available underharvested Ponderosa Pine. Timber Age and their use of cross-laminated timber (CLT) which is composed of sustainable Ponderosa Pine, epitomize true sustainability.

I talked with Kyle Hanson, co-founder of Timber Age Systems about his team’s approach and work at this innovative panel manufacturer in the heart of sustainable timber country. Thank you Kyle for leading the charge on providing innovation through sustainability in Offsite manufacturing.

Kyle and Charlie. Kyle is the one on the left!

Timber Age Systems Interview Questions

Bill Murray, Offsite Innovators: Would you summarize your current business model?

Kyle Hanson, Cofounder of Timber Age : First and foremost, Timber Age™ makes durable, attainable, high-performance homes in an off-site modular factory. The homes are produced from locally and sustainably harvested Ponderosa Pine.

Our business model leverages a local value chain and community partnerships supplying design, engineering and installation support. This focus on circular economics allows Timber Age™ the chance to address forest health, housing constraints and job creation while significantly improving the built environment in terms of embodied and operational carbon content.

Secondly, Timber Age™ is continually refining a replicable production model in preparation for widespread expansion over the coming decade. This production model prioritizes shared ownership, a short amortization of investment capital and a flexible and adaptive learning environment supplied through the Timber Age Operating System (TAOS).

.

Bill: What inspired you to found Timber Age Systems?

Kyle: After spending four years as the Business Unit Leader for a local wood products manufacturer working closely with the US Forest Service, I developed a curiosity to better understand how to create a use for the overabundance of Ponderosa Pine in our region.

In addition to unhealthy forests, many teachers of my two daughters struggled to establish stable local housing. An inability to establish an “anchored” existence in our community frequently ended in job openings. This damaging pattern of churn repeats across public servant roles resulting in instability for schools and local government.

Last, but not least, many in our community maintain seasonal and overlapping jobs in an attempt to achieve sustainable adjusted median income (AMI) levels. My background studying and implementing Lean Operating Systems to achieve world-class manufacturing operations illustrates how the creation of predictable, safe and rewarding skilled labor jobs could help create more anchored community members.

A 2018 USFS Wood Innovation Grant award catalyzed an amazing group of individuals collaborating around the key market definition and challenges. This group problem solving process eventually allowed our co-founder Andy Hawk to enter the fray as team member number two.

Most of the idea development has followed the ideas inherent in the world of Lean (Operational Excellence, TPS, etc). These themes surrounding rapid experimentation and improvement have been codified in the excellent book “The Lean Startup” by Eric Ries. Our team is continually working to clearly identify a problem and its causes and then establish an experiment where we can test a hypothesis to address the problem. When we do this in a disciplined and continuous manner, Timber Age™ gets better and we all get smarter and more connected as a team.

.

Bill: How would you describe some of the most innovative solutions Timber Age Systems has developed for offsite construction?

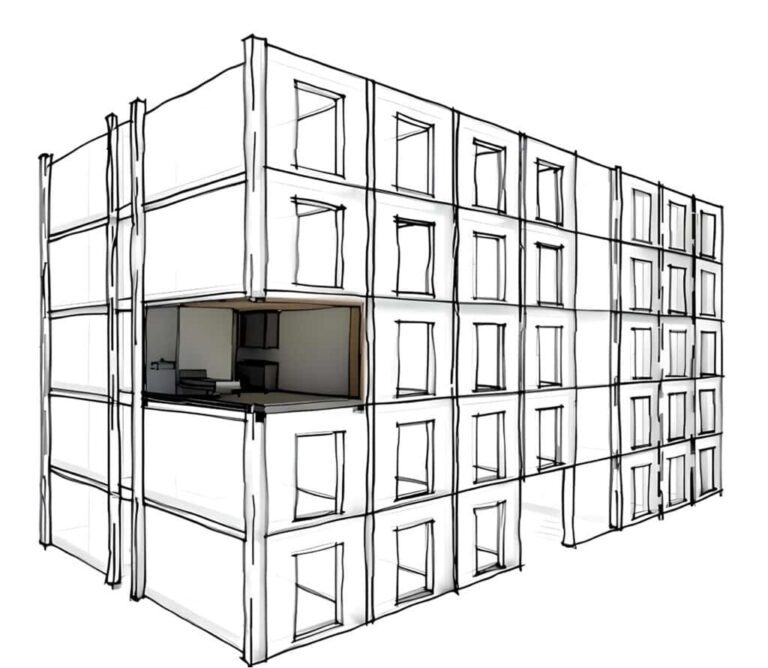

Kyle: Our approach to vertical integration and small scale manufacturing of Cross-Laminated Timber (CLT) seems to be a differentiating factor in the worlds of mass timber and off-site manufacturing. We don’t have a huge factory with giant cranes, and yet we create beautiful enclosures which are easily installed.

In the long-term, we believe our integrated approach to helping create housing, fulfilling jobs and healthy forests will provide a powerful model for sustainable community development around the world.

.

Bill: In what way does Timber Age prioritize sustainability in its innovative approaches to construction?

Kyle: Timber Age™ is intensely focused on both the embodied carbon and operational carbon of buildings. A key mission metric for our team is miles traveled/ pound. In this way, we can look at the many components in one of our assemblies and create a weighted average of the total waste associated with transportation. In addition, our assemblies are almost completely foam-free.

Our CLT is constructed from trees which would have otherwise released carbon dioxide into the air due to overcrowding, fire and disease.

This approach to using a carbon-sequestering structural material (CLT) combined with recycled cellulose insulation (also carbon-sequestering) means an enclosure with net-zero embodied carbon and a home with super low operational carbon emissions due to the passive house building science behind our system design.

The Timber Age™ Modular Building System (TAMBS) incorporates low-carbon materials and is designed to meet the Passive House building standard.

.

Bill: What are some of the biggest challenges you have faced in gaining an acceptance of your innovative approach both locally and regionally?

Kyle: Since the Timber Age Modular Building System (TAMBS) contains many unique innovations, our biggest challenge was proving out the ability to manufacture the system at a hyper-local scale. After proving out the system, our biggest challenge has been builder uptake of our approach. Introducing an innovative building system into a marketplace where demand for the status quo is still outstripping the capacity of local builders doesn’t incentivize builders to seek out or make time for learning a new system even if many of the builders understand and appreciate the inherent value proposition.

Matt Betts, Value Stream Manager

The world of building, much like the world of healthcare, encompasses multiple customers with varying definitions of value. We are working hard to collaborate with as many stakeholders as possible to ensure the highest level of value is created for each step off the value chain. We believe our system is easy for designers to implement, very quick and effective to install for the builders and beautiful, durable and very energy efficient to help enforce the inherent value for the end users.

.

Bill: How important are collaborations and partnerships as you seek to grow your business?

Kyle: Timber Age™ would not exist without the help of our local forest collaboratives, fellow building scientists, collaborating designers and contractors and especially the funding and support of the US Forest Service and our incredible mission-driven shareholders.

.

Bill: What are you short- and long-term goals for Timber Age Systems and what philosophy did you use in developing these?

Kyle: Short-term: Get our new interim factory running to produce our current backlog of projects and hire another ten great team members.

Long-term: Construct our new prototype factory and housing models in Mancos and then replicate this model across all viable markets to help create 1000+ fulfilling jobs and hundreds of thousands of durable, beautiful high-performance housing units around the world.

Our philosophy around planning, Hoshin Kanri, follows the teaching and examples of Toyota and other world-class companies.

Tens of thousands of acres of sustainable pine being put to use by this innovative panelizer in Durango, CO. Sustainability is more than a buzzword at Timber Age Systems, its a way of doing business and a way of life.

.

Bill: I want to thank you , Kyle, for a very insightful, behind the scenes look at what you and Timber Age Systems are currently doing and what you have planned for the future.

Bill Murray, co-founder of Offsite Innovators, is a 40-year veteran in the Offsite industry. His goal is to assist in the growth of the industry by presenting and sharing innovation.

CLICK HERE if you would like to be interviewed about something innovative you have designed or are currently using.