What If Canada Became the 51st U.S. State? Implications for Offsite and Modular Construction

I find the idea of Canada becoming the 51st state of the United States, as suggested by Kevin O’Leary during a recent interview, as bold and provocative. While this concept remains speculative, it opens a fascinating window into the potential implications for the offsite and modular construction industries.

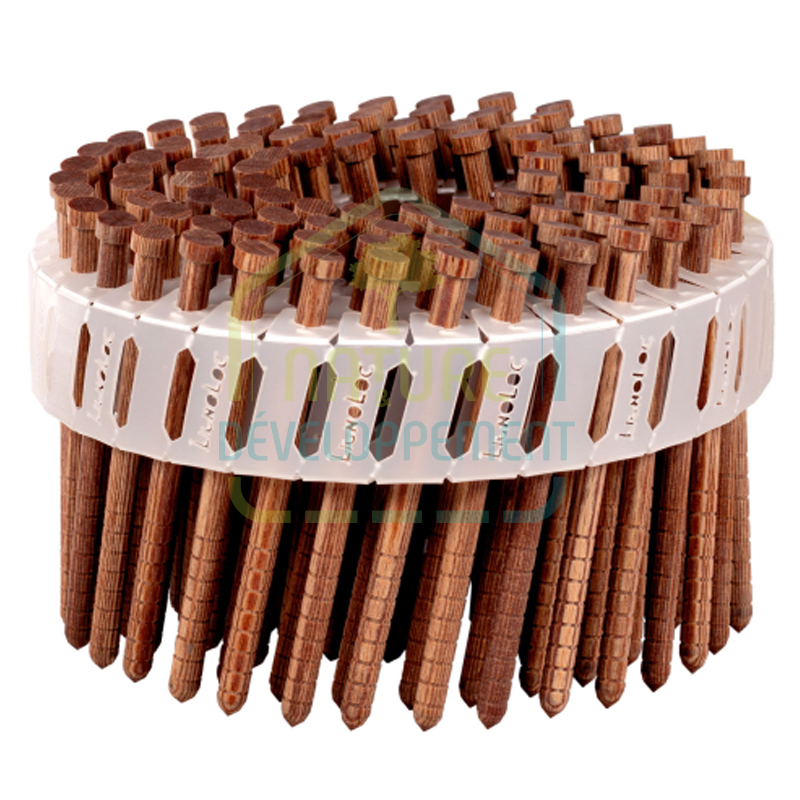

Top and above photos – BECC

One intriguing twist in this hypothetical scenario is the possibility of the U.S. adopting the National Building Code of Canada (NBC) as the basis for a unified national code. Could this lead to a new era of harmonized regulations, economic growth, and innovative collaboration?

Harmonizing Building Codes: A Game-Changer for Construction

Currently, the U.S. and Canada operate under different building codes. The U.S. primarily uses the International Building Code (IBC) or state-specific regulations, while Canada’s NBC provides a uniform framework across provinces. If Canada were to become a U.S. state, adopting the NBC as the foundation for a unified North American building code could simplify construction practices across the continent.

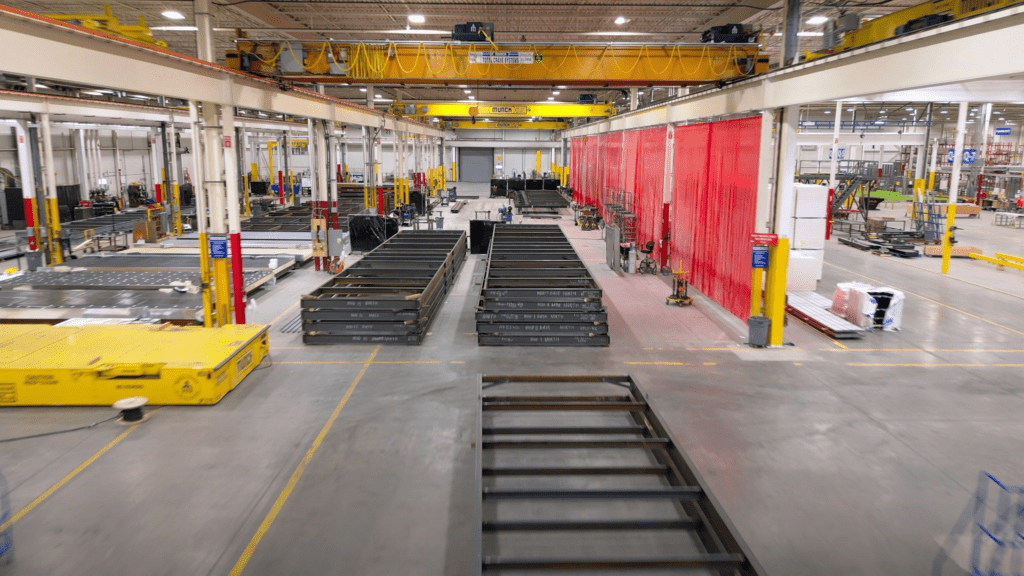

Photo – Assembly Corp.

The NBC is renowned for its clarity, adaptability to regional climates, and focus on sustainability. By integrating it into the U.S., modular construction companies could benefit from standardized regulations, eliminating the need to navigate a patchwork of state and local codes. This harmonization could:

Streamline Cross-Border Projects: A unified code would reduce compliance hurdles for companies operating in both countries.

Encourage Innovation: Consistent regulations could incentivize investment in advanced construction techniques, such as robotics and 3D printing, without worrying about regional discrepancies.

Boost Sustainability: The NBC’s emphasis on energy efficiency and environmental considerations could set a higher standard for green building practices across North America.

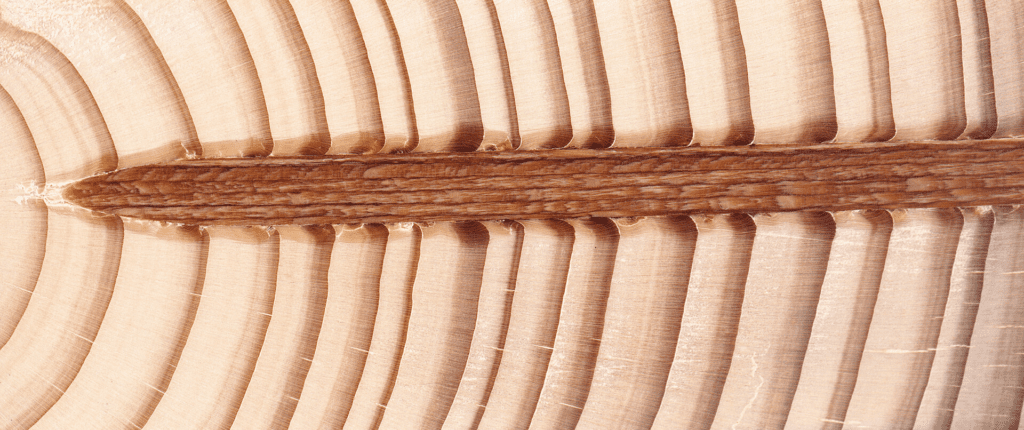

photo – FERO International Inc.

Economic Integration: Opportunities and Challenges

Canada joining the U.S. would create one of the largest unified construction markets in the world. The modular industry could experience both opportunities and challenges in such an environment.

Opportunities:

Market Expansion: Canadian modular manufacturers would gain seamless access to the vast U.S. housing market, presenting enormous growth potential.

Labor Mobility: A unified labor pool could help address skilled labor shortages that have long plagued the construction sector.

Increased Investment: U.S. companies might be more inclined to invest in Canadian modular factories, given the absence of trade barriers and currency fluctuations.

Challenges:

Increased Competition: U.S. modular firms would enter Canadian markets, potentially squeezing smaller, local players.

Cost Adjustments: Canadian companies might need to adapt to different wage structures, healthcare costs, and tax policies.

Adopting Canadian Practices: Sustainability and Innovation

One of Canada’s strengths lies in its focus on sustainability and innovation in construction. Modular housing in Canada often incorporates features such as net-zero energy systems, advanced insulation techniques, and designs suited for extreme climates. If the U.S. adopted these practices alongside the NBC, it could elevate construction standards across the board.

For example:

Energy Efficiency: Modular homes built to NBC standards could dramatically reduce energy consumption, aligning with global climate goals.

Resilient Designs: Adapting Canadian techniques for colder climates could benefit northern U.S. states, while milder designs from southern states could find use in Canada’s temperate regions.

Sustainability Leadership: By embracing the NBC, the U.S. could position itself as a global leader in sustainable construction practices.

Photo – ROC Modular

Logistics and Infrastructure: Laying the Groundwork

Integrating Canada into the U.S. would require significant investments in infrastructure. Transportation of modular units and construction materials over long distances has always been a logistical challenge for the industry. Improved infrastructure across a unified North America could:

Reduce Costs: Enhanced rail and road networks would lower transportation expenses for modular factories.

Expand Reach: Factories located near the U.S.-Canada border could serve both markets more efficiently.

Encourage Hub Development: Strategic locations could emerge as manufacturing and distribution hubs, boosting local economies.

Unified Currency: Stabilizing Costs

Another major shift would be the adoption of the U.S. dollar in Canada. For modular manufacturers, this could stabilize costs for materials and labor by eliminating currency exchange risks. It could also simplify cross-border transactions and make budgeting more predictable for international projects.

Innovation Through Collaboration

Combining the resources and expertise of both countries could spur groundbreaking advancements in modular construction. Research and development efforts might focus on:

Robotics and Automation: Joint ventures could accelerate the adoption of automated production lines, reducing costs and increasing efficiency.

3D Printing: Integrating Canadian and U.S. expertise could make large-scale 3D-printed housing a viable solution for affordable housing.

AI and Smart Technologies: Collaborative efforts could lead to smarter, more connected modular homes.

Cultural and Policy Considerations

Despite the potential benefits, merging two distinct nations into a single entity would not be without challenges. Political, cultural, and social differences could create friction in aligning construction practices and policies.

For instance:

Regulatory Resistance: Some U.S. states might resist adopting the NBC, viewing it as a departure from established norms.

Cultural Identity: Canadians’ strong sense of national identity might lead to pushback against Americanizing their construction industry.

Environmental Policies: Reconciling Canada’s stringent environmental standards with less uniform U.S. practices could be contentious.

photo – Quality Homes

The Bigger Picture: Building for the Future

Ultimately, the idea of Canada becoming the 51st U.S. state raises as many questions as it does possibilities. For the offsite and modular construction industries, the implications could be transformative. A unified building code, particularly one based on Canada’s NBC, might serve as a catalyst for innovation, efficiency, and sustainability.

But challenges abound. From cultural resistance to economic adjustments, navigating this new reality would require careful planning and collaboration. For industry leaders, the potential rewards of a unified market and regulatory framework make the hypothetical scenario worth considering—even if it remains firmly in the realm of speculation.

Would adopting the National Building Code of Canada truly unify North American construction practices? Could it drive the offsite and modular construction industries to new heights? Or would the complexities of integration outweigh the benefits? These are questions that may never need definitive answers but are worth pondering as we envision the future of construction.