Pioneering Technology and Overcoming Obstacles with Thermal Studs – Brian Iverson Part Two

Behind every groundbreaking innovation lies a journey of overcoming obstacles, and for Brian Iverson, the path to creating Thermal Studs was no exception. In Part One of his Interview, we talked about how solving problems in sustainability and energy efficiency was the idea for his innovative product the T-Stud. Today, he finished our interview by discussing the challenges he faced.

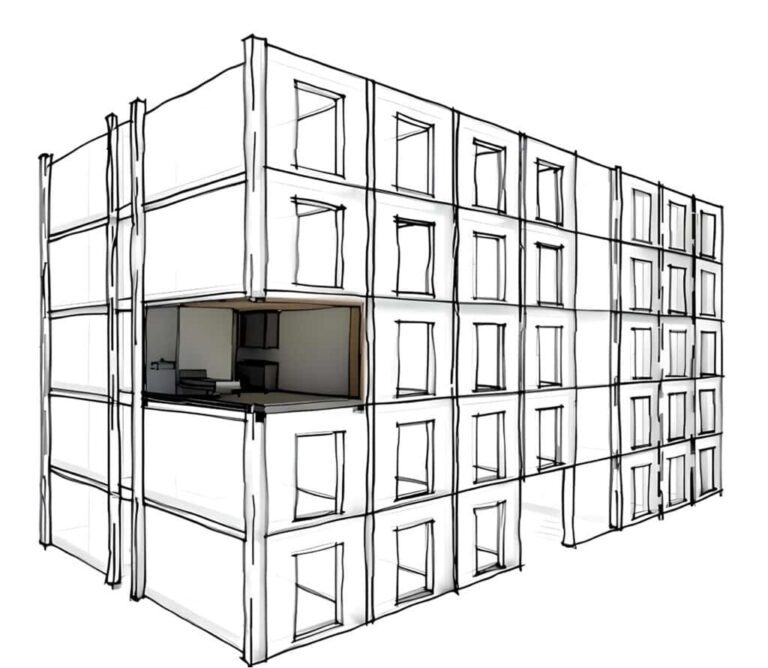

His pioneering system integrates closed-cell foam insulation and reimagined structural configurations to meet both thermal efficiency and strength requirements. By rethinking traditional building components, Iverson crafted solutions like the RhinoStud™ and WarmStud™, addressing challenges that have long plagued the construction industry—thermal bridging, energy loss, and structural vulnerability to extreme conditions. His work stands as a testament to the transformative power of combining modern materials science with practical building needs.

However, breaking through regulatory, production, and market-entry barriers presented their own hurdles. Iverson’s journey demonstrates not just technological ingenuity but also resilience and adaptability, relying on partnerships and innovative production methods to bring his ideas to market. From seismic and hurricane-resistant materials to cost-effective continuous insulation solutions, Thermal Studs redefines what it means to build sustainably and reliably in a constantly evolving industry.

Brian Iverson, Founder of TStud

Gary Fleisher: How did you ensure their durability, safety, and compliance with industry standards?

Brian Iverson: We take great care to exceed both U.S. and Canadian building codes. Each of the Thermal Studs products undergoes rigorous testing to meet or surpass ASTM (American Society for Testing and Materials) standards. This ensures they’re compliant in terms of structural integrity, energy efficiency, and thermal performance.

The WarmStud™ uses traditional framing members already approved by the American Plywood Association (APA), meaning no additional testing is required for these components. However, we’ve enhanced the WarmStud™ patent by including a simple way to manufacture it within the TSUPS by “levitating” the wall, roof, or floor assembly frame off the sheathing, creating the WarmStud™ patented product with a 100% thermal break, and providing up to 1000 pounds per linear foot of “ultimate” wind load capacity when created within the WarmStud™ Panel System.

The Warmstud

These innovations offer builders a way to differentiate themselves from other competitors with the durability, safety, and energy efficiency required for today’s challenging construction environment.

Gary: How does your products contribute to sustainability, and what role do you see it playing in the broader movement towards eco-friendly and energy-efficient buildings?

Thermal Studs is all about sustainability. By reducing heating and cooling loads by up to 50%, our products directly cut down on energy consumption. This is achieved through superior insulation and the elimination/minimization of thermal breaks, which waste energy in traditional framing systems.

In addition to energy efficiency, our products are designed for durability, minimizing the structure’s carbon footprint. We demand our licensees use closed-cell foam insulation made with the HFO blowing agents, which have a global warming potential of ~4, contributing to reduced environmental impact.

As more builders and homeowners adopt eco-friendly practices, Thermal Studs provides an affordable, scalable solution that exceeds the strictest energy codes. Our products are designed to help the construction industry meet the growing demand for sustainable buildings, ultimately reducing our carbon footprint and conserving natural resources.

7. From concept to reality, what has been the most unexpected lesson or challenge you’ve encountered, and how has it shaped your approach to innovation?

The journey from concept to reality has been full of unexpected challenges. From supply chain disruptions to closing borders, production issues, and equipment delays—it has been a constant learning process. One key lesson I’ve learned is that innovation is about persistence. A patent is just a dream until you get it to market and make it viable.

At times, the hurdles felt insurmountable, especially when builders resisted change. But each setback reinforced my belief that true innovation requires determination. It’s not just about inventing; it’s about creating a viable, scalable solution that addresses real-world problems.

8. Where do you see Thermal Studs’ place in the future of construction, and what impact do you hope they will have on the way buildings are designed and constructed over the next decade?

I see Thermal Studs playing a key role in the future of construction, particularly as the demand for energy-efficient, sustainable, and resilient buildings continues to grow. Our products help builders meet increasingly strict energy codes and provide solutions that withstand the harshest conditions, making them ideal for both residential and commercial projects.

Over the next decade, I hope Thermal Studs will become a cornerstone in the evolution of building materials, helping the industry shift toward eco-friendly and energy-efficient construction practices. I envision our products becoming a standard in the building industry, offering cost-effective, high-performance solutions that reduce both construction costs and long-term operational expenses.

Ultimately, I want to leave a legacy of innovation, where buildings are designed to be energy-efficient, structurally sound, and sustainable for generations to come. Imagine this…the RhinoStud™ made from 316L stainless steel.

Brian, thank you for this unique interview and I hope you never stop bringing your innovations to the construction industry.