Revolutionizing Modular Management: An Interview with Offsight’s Founder on Transforming Project Planning for Offsite Construction

Having spent over 40 years in the offsite construction industry as a GM and COO, I’m no stranger to the challenges of managing modular manufacturing projects. My team and I constantly navigated a sea of spreadsheets, charts, and verbal communications, trying to keep everything from design approvals to deliveries in sync. Needless to say, when I came across Offsight’s project management software, it immediately caught my attention.

Back in the day, we would have eagerly explored how Offsight’s innovative tool could simplify the planning, tracking, and communication challenges that came with modular projects. From real-time updates to streamlined processes, this software offers solutions that are as close to seamless as I’ve seen for managing everything from pre-production to post-delivery—engaging all key stakeholders, even those on-site.

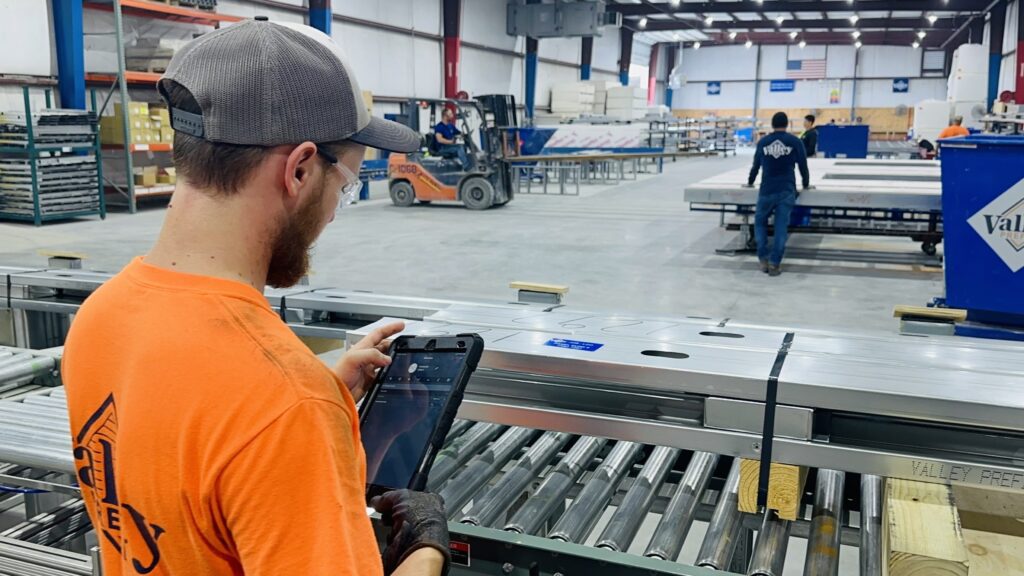

Panel fabricator Valley Interior Systems leverages Offsight for collaborating and coordinating with stakeholders during offsite projects

But don’t just take my word for it. Offsight has case studies that show real-world applications by industry leaders already using the product. If you’re in the offsite manufacturing space—whether you deal with volumetric builds or components—this is worth a deep dive.

In this interview, I sit down with Andrew Xue, co-founder of Offsight, to learn more about the innovation driving their platform and how it’s transforming the way we manage modular projects. Let’s dig into how Offsight can reshape your operations.

Bill Murray Offsiteinnovators co -founder: Offsight is all about optimizing construction project management. Can you tell us the story behind how Offsight was founded and what specific gap in the industry you aimed to fill?

Andrew Xue,COO & Co-Founder at Offsight

Andrew Xue co-founder of Offsight: Offsight was founded from the consulting work and experience of its founders, Vikas Murali and Andrew Xue with a combined two decades worth of experience in prefabrication. We had worked with many project manufacturers whose process involved designing for manufacturing and assembly (DfMA). They realized that the DfMA industry lacked a project and production management software that could be adapted from project to project to meet their changing project specific manufacturing workflows. Working with their original consulting clients they built a minimum viable product (MVP) that would then become Offsight.

Bill: Offsite construction is booming, but managing projects can still be complex. How does Offsight streamline project management, and what makes your platform stand out from other software solutions?

Andrew: Offsight is built specifically for manufacturers and prefabricators who’s DfMA process requires different manufacturing workflows for each product design. Offsight was built as a fully cloud-based solution with both mobile and desktop interfaces to allow for real time collaboration and communication from the floor. We also provide a full suite of solutions to manage a prefab project from planning and forecasting, through production, shipment, delivery, and installation. Our software is built specifically for prefabricators who follow a DfMA process and therefore is a better fit than off the shelf manufacturing operations management or generic project management solutions.

Bill: Data is critical in construction. How does Offsight harness data to improve the efficiency and accuracy of offsite building processes, and what kind of real-time insights can users expect?

All data collected in Offsight is recorded in real-time from the prefab floor and throughout the offsite construction project lifecycle. The time series data we collect includes everything from production progress to material consumption and labor tracking on who worked on specific products and during which process. This data is then consolidated and can be visualized with dynamic charts and dashboards using our Real Time Analytics feature set.

Volumetric steel modular manufacturer Z Modular leverages Offsight to track quality, conformance, and rework.

Bill: What role does Offsight play in improving collaboration between different stakeholders in offsite projects, from modular, panel, and component manufacturers to project managers and contractors?

Andrew: Offsight has an unlimited user model, where customers can add everyone from floor operators and supervisors to project managers, estimators, executive management and even third-party inspectors, general contracting partners, and project owners. Our Reports & Auditing feature set includes daily production progress updates, quality or non-conformance issues and shipment sign-offs can then be tracked and sent within Offsight

to all project stakeholders to ensure everyone has the latest updates and whether the prefab projects are still on track to be completed on time and within budget.

Bill: In what ways does Offsight’s platform contribute to sustainability and waste reduction in offsite construction? Are there any success stories that highlight this impact?

Andrew: Many of Offsight’s customers leverage our Materials and Inventory Management feature set which allows them to track waste in real-time during the materials receiving process or during assembly and installation. Customers can then review the root cause of wasted materials via Offsight’s analytics dashboard to see if process improvements can help reduce assembly errors. Offsight customers can also determine if certain suppliers are shipping defective parts or if parts are damaged on receipt, in which case switching to more reliable vendors may be the solution to improving overall waste reduction.

Luxury modular manufacturer Northstar Systembuilt leverages Offsight to track production progress from the shop floor.

Bill: Looking ahead, how do you see technology like Offsight evolving, and what future innovations in project management are you most excited about for the offsite construction industry?

Andrew: I think technology like Offsight has the real potential to enable the growth of offsite construction by helping prefabricators deliver on the promise. The promise being faster project delivery at lower cost and higher quality than traditional jobsite construction. By leveraging technology like Offsight, prefabricators can actively manage their production progress, materials management and labor to make ensure they are delivering on their goals.

Bill: What do you see as Offsight’s biggest challenge in growing your business?

Andrew: Our biggest challenge is delivering the right features and functionality to support customers at every stage of their offsite construction journey, whether they’re planning their first factory layout or managing multiple production lines across several factory locations. It’s crucial for Offsight to clearly communicate how our tools can address their specific needs. Additionally, we aim to encourage prefabricators to adopt technology early on, as it can be a key differentiator in the success of their projects. When our customers thrive, it not only benefits them but also drives more engagement, interest, and investment in offsite construction, ultimately advancing the entire industry.

Bill: Thanks to Andrew Xue of Offsight for opening the door to an awareness of what’s out there. Whether you are a manufacturer or a vertically integrated developer/manufacturer, I would encourage you to check out their website. At the very least there is much food for thought.