The Growing Role of Sensor Data in Modular Construction: Enhancing Safety, Efficiency, and Quality Control

Today, technology is becoming more than just a tool for convenience—it’s an essential part of the process. As modular construction gains traction for its ability to deliver cost-effective, efficient, and environmentally sustainable housing, integrating sensor data into the manufacturing process has become a vital component of success.

Modular construction, which involves building modules in a factory setting before transporting and assembling them on-site, benefits enormously from using advanced sensor technology. Sensor data not only ensures the safety of workers but also helps monitor the quality and performance of the modules before they are shipped to the construction site.

What is Sensor Data?

Sensor data is generated when a sensor detects input from its surrounding environment. This input could be in the form of light, temperature, motion, humidity, or sound, among others. Sensors process these inputs and provide real-time feedback or alerts based on the readings, enabling swift decision-making. In modular construction, sensor data plays a critical role in monitoring environmental conditions, structural integrity, and safety, both during the fabrication process in the factory and when modules are transported and installed at the construction site.

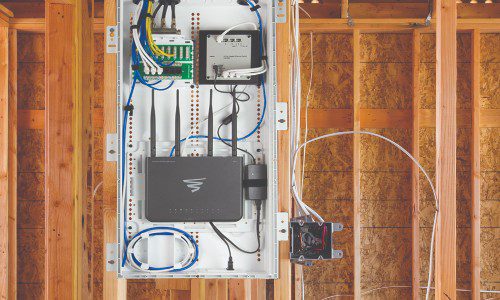

The integration of wireless connectivity into many sensors has also enhanced the ability to monitor and control these devices remotely, offering a seamless way to ensure the quality and safety of modules even after they leave the factory floor.

The Role of Sensor Data in Modular Construction

Sensor data is essential throughout the entire lifecycle of a modular construction project, from factory assembly to transportation and installation. Various types of sensors help monitor critical factors that impact both the safety of workers and the long-term durability of the buildings. Here are several ways sensor data is being used in modular construction:

Vibration Sensors: Ensuring Structural Stability During and After Construction

Vibration sensors play a crucial role in monitoring the structural stability of modular units. These sensors detect any movement or vibrations that could indicate instability within the structure. During the factory assembly process, vibration sensors can be used to detect structural flaws or weaknesses in connections, allowing manufacturers to address these issues before the modules are shipped to the job site.

Once the modular units are being transported, vibration sensors continue to play a role by monitoring the forces exerted on the structures during transit. Modular units, particularly those transported over long distances, can experience stress due to road conditions or handling. Vibration sensors alert manufacturers to any significant movements that could damage the structure during transport, ensuring that the module arrives on-site in optimal condition.

Humidity Sensors: Protecting Materials During Fabrication and Transport

Humidity is a critical factor in construction, particularly in environments where building materials are sensitive to moisture. In modular construction, humidity sensors are installed in factory settings to monitor moisture levels throughout the production process. Excessive humidity can degrade construction materials like wood, insulation, and drywall, leading to structural issues or material failure later on.

For instance, if humidity levels rise beyond acceptable limits, sensors can alert factory workers to take corrective action, such as adjusting ventilation or activating dehumidifiers. Additionally, humidity sensors can be left in the modular units during transportation to monitor the environment and prevent moisture-related damage en route to the job site. This proactive approach protects materials, ensuring they remain in pristine condition before installation.

Gas Sensors: Monitoring Air Quality for Workers and Future Inhabitants

Construction sites, particularly modular factories, can involve processes that release harmful gases or volatile organic compounds (VOCs). Gas sensors are vital in these environments, detecting unsafe levels of toxic gases such as carbon monoxide, methane, and other chemicals used in adhesives, paints, or insulation materials.

Gas sensors in modular factories protect workers from exposure to dangerous gases during the manufacturing process. These sensors can also be left inside the modular units to monitor air quality during transportation and even after installation on-site. In residential and commercial modular buildings, ensuring clean air is essential for the well-being of occupants, making gas sensors an indispensable tool for long-term safety.

Proximity Sensors: Enhancing Safety and Automation in the Factory

Proximity sensors are used to detect the presence or absence of nearby objects or people. In modular construction factories, these sensors can be installed on machinery and heavy equipment to prevent accidents. For example, proximity sensors on cranes, forklifts, and robotic assembly lines can halt operations if a worker gets too close, reducing the risk of accidents.

Moreover, proximity sensors can also be built into the modular units themselves to enable smart building features, such as automated lighting, heating, or security systems. These systems can be pre-installed and tested in the factory, allowing for seamless integration once the module is set up on-site.

Temperature Sensors: Ensuring Energy Efficiency and Performance

Temperature sensors are particularly useful in monitoring the thermal performance of modular units. In the factory, these sensors help ensure that insulation and heating systems are correctly installed and functioning as intended. By monitoring temperature data, manufacturers can detect potential issues with thermal performance early in the process, allowing them to make adjustments before shipping.

Additionally, temperature sensors can be used to monitor the conditions during transport, ensuring that materials that are sensitive to extreme temperatures, such as certain types of insulation or finishes, remain undamaged. Once installed, these sensors can continue to monitor the building’s energy efficiency, providing valuable data on heating and cooling performance.

Wireless Connectivity and Remote Monitoring in Modular Construction

One of the most transformative aspects of sensor technology is its integration with wireless connectivity and the Internet of Things (IoT). In modular construction, this allows real-time sensor data to be transmitted directly from the factory floor to cloud-based systems, where project managers and engineers can monitor conditions remotely. This capability provides invaluable insights into the production process and allows for immediate action when sensor readings fall outside acceptable parameters.

For example, vibration sensors embedded in a module’s foundation can continuously send data to engineers monitoring the construction remotely. Similarly, humidity sensors can provide updates on the factory environment or transport conditions, ensuring the integrity of the building materials before they arrive on-site. This ability to track data remotely reduces the need for on-site inspections and improves the overall efficiency of the construction process.

Benefits of Using Sensor Data in Modular Construction

Improved Quality Control

In modular construction, consistency and precision are key to delivering high-quality buildings. Sensor data ensures that every module produced meets strict quality standards by providing real-time feedback on critical factors such as structural integrity, environmental conditions, and air quality. This allows for rapid adjustments during the manufacturing process, reducing the likelihood of defects or damage.

Increased Safety

The integration of sensors in the factory enhances worker safety by monitoring hazardous conditions such as gas leaks, proximity to machinery, or excessive vibrations. This is especially important in modular construction, where factory environments often involve automated equipment and heavy machinery.

Additionally, sensors installed within modular units can ensure the safety of future occupants by monitoring air quality, structural stability, and thermal performance over time.

Cost Savings

By detecting potential issues early in the manufacturing process, sensor data helps prevent costly repairs or delays. Monitoring humidity, for instance, can prevent material degradation, while vibration sensors can identify structural weaknesses before shipping. This reduces the risk of damage during transport or installation, leading to fewer delays and lower overall costs.

Remote Monitoring and Real-Time Data

With wireless connectivity, construction teams can remotely monitor sensor data, even during transport and installation. This ability to track real-time conditions helps improve decision-making and ensures that problems are addressed before they become major issues.

Enhanced Sustainability

Sensors contribute to the sustainability of modular construction by ensuring that energy-efficient practices are maintained throughout the production process. Temperature and humidity sensors, for example, ensure that insulation and other energy-saving features are installed correctly, helping the building meet green building standards.

Final Thoughts

Sensor data is revolutionizing the modular construction industry by offering unparalleled insights into every stage of the building process, from factory fabrication to on-site installation. By monitoring environmental conditions, structural stability, air quality, and more, sensors ensure that modular buildings are built to the highest standards of quality and safety.

As wireless connectivity and IoT continue to evolve, the use of sensors in modular construction will only become more widespread, providing even greater opportunities for innovation and efficiency. With real-time data collection and remote monitoring, manufacturers and construction teams can work together to ensure that every module meets stringent safety, performance, and sustainability standards—before it even leaves the factory. In doing so, sensor data is helping to shape the future of modular construction, making it safer, more efficient, and more reliable than ever before.

.