The Future of Robotics – An Interview with the President of Framebotix

I am genuinely excited to have this opportunity to interview Yudhisthir Gauli, a true pioneer in the field of autonomous industrial robotics. His extensive experience, innovative mindset, and remarkable contributions to the manufacturing sector make him an inspiring figure. I look forward to learning more about his groundbreaking work at Framebotix.

Yudhisthir Gauli

Yudhisthir Gauli, the founder and President of Framebotix, is a visionary in the world of autonomous industrial robotics. With several decades of experience in manufacturing and a portfolio of multiple patents, Gauli is recognized as a trailblazer in transforming how modern factories operate. His career has been dedicated to pioneering advancements that integrate cutting-edge efficiency and innovative practices into the manufacturing process, fundamentally reshaping the industry.

As a full-blood robotic entrepreneur, Gauli’s contributions have had a profound impact on the evolution of autonomous industrial robotics. His work focuses on optimizing manufacturing environments, allowing factories to operate with unprecedented levels of precision, speed, and flexibility. By developing and implementing autonomous solutions, Gauli has enabled the manufacturing sector to leap forward, enhancing productivity while reducing costs and errors.

Under his leadership, Framebotix has become a leader in integrating robotics into manufacturing, helping companies around the world adopt state-of-the-art automated systems. Gauli’s journey, marked by his relentless pursuit of innovation, offers invaluable insights into the future of manufacturing and the role of robotics in driving the next generation of industrial efficiency.

Thanks, Yudhisthir, for talking with me about all innovative ways you are working on with robotics.

Gary Fleisher, Offsite Innovators: Can you describe your journey and role at Framebotix? How has your vision shaped the company’s direction and its current standing in the offsite construction industry?

Yudhisthir Gauli, Founder/President: My journey at Framebotix as both CEO and CTO has been driven by a commitment to innovation and solving challenges in the offsite construction industry. Leveraging our decade-long experience in autonomous robots and factories, We have focused on revolutionizing home manufacturing to make custom homes both affordable and durable.

Our expertise in autonomous robotics supports various offsite applications, helping our customers achieve greater efficiency and precision. My vision has shaped Framebotix’s direction, driving us to create sustainable, high-quality manufacturing processes. By emphasizing natural materials and regional manufacturing, we’ve reduced costs, increased efficiency, and minimized environmental impact.

Gary: What are some of the most innovative technologies that Framebotix is currently utilizing in offsite construction? How are these technologies improving efficiency and productivity on construction sites?

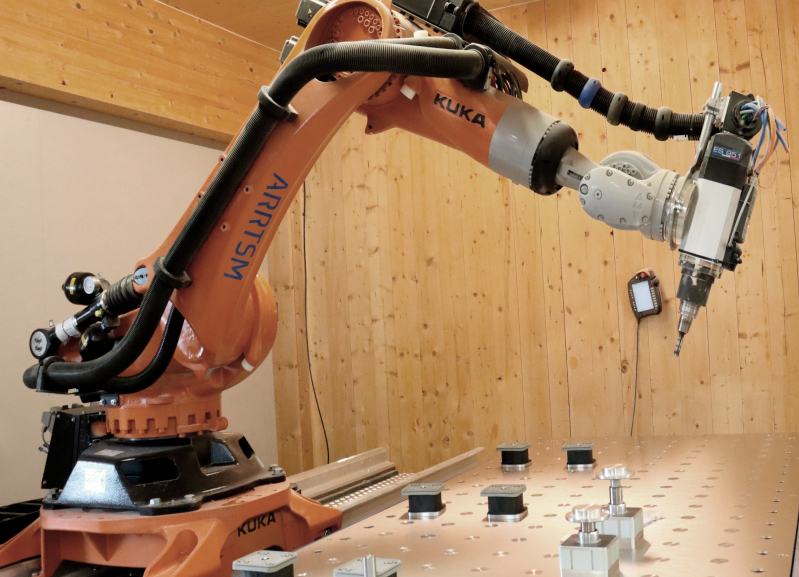

Yudhisthir: At Framebotix, we’re utilizing cutting-edge technologies that are revolutionizing offsite construction. Our AI-powered autonomous robots handle all machining, assembly, and handling applications, capable of operating 24/7 to reduce cycle times, lower costs, and ensure precise quality.

We also use a data-driven High-Performance Volumetric Manufacturing management system that optimizes manufacturing in real-time, minimizing downtime and ensuring every part meets exact specifications. Additionally, we incorporate advanced materials like cold-formed steel and sustainably sourced wood to create durable, eco-friendly components.

These innovations streamline manufacturing, boost efficiency, and enhance productivity, resulting in faster project turnarounds and superior quality outcomes for our clients.

Gary: Could you share insights into any new robotic systems or technologies that Framebotix is currently developing? How do you foresee these advancements transforming the offsite construction landscape in the near future?

Yudhisthir: At Framebotix, we’re excited to be developing our 8th generation autonomous robotic systems, which we plan to complete by the end of this year. These cutting-edge systems are designed to further enhance precision and adaptability in offsite construction, handling complex tasks like advanced machining, intricate assembly, and seamless material handling with even greater efficiency and accuracy.

One of the standout features of this new generation is the integration of AI-driven decision-making capabilities. This allows our robots to learn and adapt to various construction environments, optimizing processes in real-time and minimizing the need for manual intervention.

We believe these advancements will significantly transform the offsite construction landscape. By enabling greater customization and faster production times, our 8th generation robots will help construct high-quality, affordable homes more efficiently, while also reducing waste and environmental impact. This will move us closer to fully automated, smart construction sites, meeting the growing demand for sustainable housing.

Gary: In what ways do you believe robotics and automation will revolutionize the offsite construction industry? What specific challenges do you think these technologies will address most effectively?

Yudhisthir: I believe robotics and automation are set to revolutionize the offsite construction industry by dramatically improving efficiency, precision, and scalability. These technologies will streamline the entire construction process, from machining and assembly to material handling, allowing for faster production times and reduced costs. One of the most significant impacts will be the ability to produce custom homes at scale, something that has been challenging with traditional methods.

Specific challenges that robotics and automation will address most effectively include the skilled labor shortage, which has been a major bottleneck in the industry. With autonomous robots, we can maintain high productivity levels 24/7, reducing the reliance on manual labor and minimizing delays. Additionally, these technologies will greatly enhance quality control, ensuring that every component is manufactured to exact specifications, which reduces waste and rework.

Robotics and automation will also help tackle sustainability challenges by optimizing resource use and reducing carbon emissions through more efficient processes and the use of eco-friendly materials. In summary, these advancements will make offsite construction more efficient, cost-effective, and sustainable, ultimately transforming how we build homes and other structures.

Gary: Looking ahead, what are your predictions for the future of robotics in offsite construction over the next decade? How is Framebotix positioning itself to be at the forefront of this evolution?

Yudhisthir: Looking ahead, I see robotics igniting a revolution in offsite construction over the next decade. Rather than a gradual evolution, we are on the brink of a transformative leap where AI-driven robotic systems will redefine how we build. These robots won’t just be more autonomous—they will be capable of learning and adapting to diverse construction environments in real-time, bringing unprecedented levels of customization, speed, and precision to the industry.

This revolution will lead to fully automated, smart construction sites where robots handle nearly every aspect of the process—from design implementation to final assembly—with minimal human intervention. This shift will drastically reduce costs, enhance quality, and make sustainable practices the industry norm.

At Framebotix, we are positioning ourselves at the forefront of this revolution. Our development of 8th-generation autonomous robotic systems, set to be completed by the end of this year, is a prime example of how we’re leading the charge. These advanced systems are engineered to tackle complex tasks with even greater precision and efficiency, directly addressing critical challenges like labor shortages, cost control, and sustainability.

In addition, our forward-looking manufacturing technology, incorporating closed-loop systems and comprehensive traceability, will further revolutionize the industry. These innovations will ensure that every aspect of production is monitored, optimized, and documented, delivering unparalleled quality and accountability.

By staying ahead of technological advancements and maintaining a sharp focus on customer needs, Framebotix is poised to lead the next wave of innovation in offsite construction, helping to shape a bold and transformative future for the industry.

Gary: What a unique insight into how robotics will help the future of offsite construction. Yudhisthir, thank you for talking with me about all the things you are working on.

Contact Yudhisthir Gauli: [email protected]

Framebotix website: https://framebotix.com/

CLICK HERE if you would like to be interviewed about something innovative you have designed or are currently using.