Innovations in Turning Recycled Waste into Construction Boards

Sweden’s Recoma Leads the Way

In the serene landscapes of Sweden, a quiet yet powerful revolution is brewing in the construction industry. As global concerns about sustainability and environmental impacts mount, a Swedish company named Recoma is pioneering an innovative solution: transforming recycled waste into robust construction boards. This breakthrough not only addresses the ever-growing waste crisis but also presents a sustainable alternative to traditional building materials. In this in-depth article, we will explore Recoma’s journey, the process of creating these eco-friendly boards, the numerous benefits they offer, and their broader implications for the future of construction.

The Problem with Traditional Building Materials

The construction industry has long relied on materials like concrete, steel, and timber, each carrying a significant environmental footprint. Concrete production alone accounts for around 8% of global CO2 emissions, while deforestation for timber depletes precious natural habitats. Additionally, the industry is notorious for generating vast amounts of waste. In the European Union, construction and demolition waste represents about 25-30% of all waste generated. These practices contribute to greenhouse gas emissions, resource depletion, and environmental degradation. Enter Recoma, with a vision to turn this paradigm on its head.

Recoma’s Genesis

Recoma’s story begins with a simple yet profound idea: what if we could take the waste plaguing our planet and transform it into something valuable? Founded in 2015, Recoma set out to create a sustainable product from materials that would otherwise be discarded. The founders, driven by a passion for environmental stewardship and innovation, embarked on a journey to develop construction boards from recycled waste. Their goal was to create a product that was not only environmentally friendly but also competitive in performance and cost.

Max Rosenberg, Founder and CEO

The Innovative Process

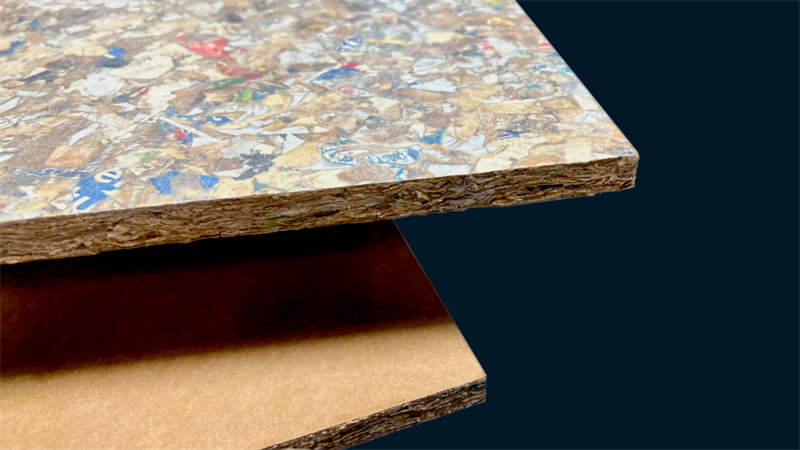

Recoma has perfected a method to convert recycled waste, particularly plastics and wood fibers, into high-quality construction boards. This process involves several meticulous steps:

Collection and Sorting: Recoma sources its raw materials from various waste streams, including post-consumer plastic waste and industrial wood residues. Partnerships with recycling centers, municipalities, and industries ensure a steady supply of quality waste. The materials are meticulously sorted to eliminate contaminants and ensure uniformity.

Shredding and Cleaning: The sorted waste undergoes shredding to break it down into smaller, manageable pieces. This is followed by an intensive cleaning process to remove any remaining impurities. This step is critical to ensure the final product’s integrity and performance.

Blending and Compression: The cleaned waste materials are blended in specific ratios to create a homogenous mixture. This mixture is then subjected to high pressure and temperature in a state-of-the-art press, where it is compressed into solid boards. This process not only binds the materials together but also enhances their strength and durability.

Finishing Touches: The freshly pressed boards are cut, sanded, and finished to meet specific requirements. They can be customized in terms of size, thickness, and surface texture, making them versatile for a wide range of construction applications.

.

Benefits of Recycled Construction Boards

The construction boards produced by Recoma offer a multitude of advantages over traditional materials:

Environmental Impact: By utilizing recycled waste, Recoma significantly reduces the volume of waste directed to landfills and incinerators. Moreover, the production process has a substantially lower carbon footprint compared to the manufacturing of traditional building materials.

Durability and Performance: Recoma’s boards are designed to withstand the rigors of construction. They exhibit excellent resistance to moisture, pests, and fire. Their robustness and performance in various environmental conditions make them suitable for both indoor and outdoor applications.

Cost-Effectiveness: The use of recycled materials can lower production costs, providing builders and developers with a cost-effective alternative without compromising quality or performance.

Aesthetic Flexibility: These boards can be produced in a variety of finishes and textures, offering architects and designers creative freedom in their projects. Whether it’s for sleek modern interiors or rugged outdoor structures, Recoma’s boards can be tailored to meet diverse aesthetic preferences.

.

Broader Implications for the Construction Industry

Recoma’s success is more than just a win for sustainability; it signals a transformative shift in the construction industry. Here are some broader implications of their pioneering work:

Reduction in Raw Material Consumption: As more companies adopt similar practices, the demand for virgin raw materials could decrease. This shift would alleviate the environmental impact associated with resource extraction and processing.

Waste Management Solutions: Recoma’s approach offers a practical and scalable solution to the global waste problem. By creating a viable market for recycled materials, they encourage better waste management practices across industries.

Policy and Regulation: Governments and regulatory bodies are taking notice of sustainable innovations like those of Recoma. Policies and incentives promoting the use of recycled materials in construction could become more prevalent, driving industry-wide adoption.

Market Dynamics: As awareness of the environmental and economic benefits of recycled materials grows, market demand is likely to shift. This change will encourage more companies to invest in sustainable technologies, fostering innovation and competition.

Challenges and Future Directions

Despite the promising advancements, Recoma faces several challenges. Ensuring a consistent supply of high-quality waste materials, maintaining cost competitiveness, and gaining market acceptance in an industry dominated by traditional materials are significant hurdles. However, Recoma remains optimistic. Ongoing research and development, coupled with increasing environmental consciousness, are expected to help overcome these challenges.

.

Recoma’s future plans include expanding their production capabilities and forging partnerships with construction companies and governments. By collaborating with key stakeholders, they aim to promote the widespread adoption of recycled construction materials. Their vision aligns with global efforts to create a circular economy, where waste is continually repurposed, reducing environmental impact and conserving resources.

Recoma’s journey from a bold idea to a leading innovator in sustainable construction is a testament to the potential of recycling in building a greener future. By turning recycled waste into high-quality construction boards, Recoma is not only reducing waste and conserving resources but also setting a new standard for sustainability in the construction industry. As the world grapples with environmental challenges, the lessons learned from Recoma’s success will be invaluable in shaping a more sustainable and environmentally friendly future. Through continued innovation and collaboration, the construction industry can build a legacy that future generations will be proud of—one recycled board at a time.

CLICK HERE if you would like to be interviewed about something innovative you have designed or are currently using.